Grundfos Shaft Seal Kit

Auxiliary impeller seal

No need for shaft seal water: Use the centrifugal force generated by the auxiliary impeller to balance the medium pressure and avoid leakage.

Good sealing effect: No dilution of the medium, suitable for single-stage pumps or the first stage of multi-stage series connection.

Power loss: Part of the pump outlet pressure energy needs to be consumed to convert into power, which may increase energy consumption.

1. Packing seal

The packing seal is one of the most common shaft seal types in slurry pumps. It has a simple structure, low price and easy maintenance. The packing seal is mainly composed of packing, gland and bolts. The gland applies pressure to the packing so that it fits tightly on the shaft to achieve a sealing effect. The packing seal is suitable for conveying general media such as water, but is generally not suitable for petroleum and chemical media, especially for precious, explosive and toxic media. This is because the packing seal has a large leakage, large power loss and a relatively short service life.

2. Auxiliary impeller seal (dynamic seal)

The auxiliary impeller seal is also called a dynamic seal. Its working principle is to achieve a sealing effect through the centrifugal force generated by the rotation of the auxiliary impeller. The auxiliary impeller seal has reliable performance, low price and easy maintenance. It is suitable for conveying media containing more solid particles, such as slurry pumps and slurry pumps in the phosphoric acid industry. However, the power loss of the auxiliary impeller seal is large, and the life of the parking seal device is short.

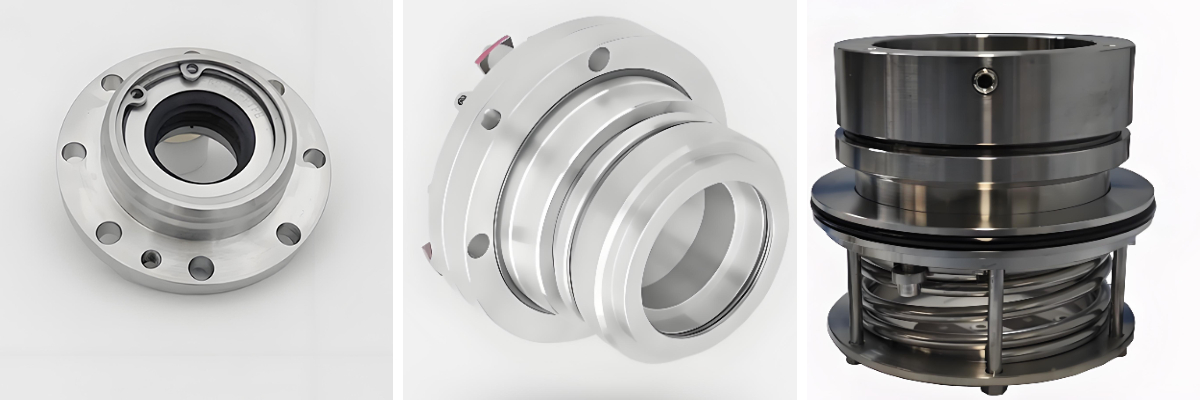

3. Mechanical seals

Mechanical seals are also called face seals. They have good sealing effects, small leakage and long service life. Compared with packing seals and impeller seals, mechanical seals have better wear resistance and corrosion resistance. They are suitable for conveying petroleum and chemical media and can be used for various media with different viscosities, strong corrosiveness and particles. The price of mechanical seals is relatively high, and the processing, installation, repair and maintenance requirements are also high. However, as China's requirements for environmental protection are getting higher and higher, the number of users of mechanical seals is gradually increasing, because their small leakage is conducive to protecting the production environment.