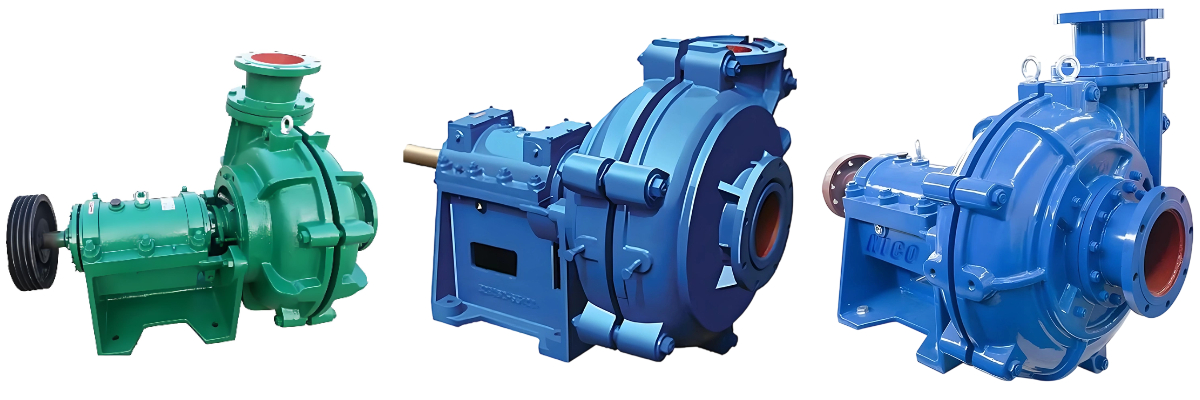

Submersible Pumps Boost Efficiency in Mining, Power, and Environmental Sectors

Industrial submersible pumps expand their application areas and become key equipment in many industries

Recently, the application of industrial submersible pumps in many fields has made significant progress. With its efficient and reliable performance, it has become a key equipment to ensure the production and operation of various industries.

In mining, industrial submersible pumps undertake important tasks such as underground drainage and slurry transportation. A relevant person in charge of a large mining enterprise said: "The mining operation environment is complex. If the accumulated water and slurry cannot be discharged in time, it will not only affect the mining progress, but also pose a safety hazard. The stable operation of industrial submersible pumps allows us to efficiently solve these problems and ensure safe and orderly production." With the increase in mining depth and the expansion of scale, higher requirements are placed on the head, flow and wear resistance of submersible pumps. Some companies have developed submersible pumps with high head, large flow and new wear-resistant materials to meet the needs of complex working conditions in mines.

The power industry is also an important application field for industrial submersible pumps. In thermal power plants, submersible pumps are used for circulating water transportation, ash discharge and other links. In the circulating water system, the submersible pump delivers cooling water to various equipment to ensure the normal operation of the unit; when processing ash, the ash slurry containing a large amount of solid particles can be transported to the treatment site. A technician from a power plant said: "The performance of the submersible pump directly affects the operating efficiency and environmental protection indicators of the power plant. The new energy-saving submersible pump we selected not only improves the transportation efficiency, but also reduces energy consumption."

In chemical production, since the transported medium is often corrosive, the corrosion resistance of the submersible pump is extremely high. Industrial submersible pumps play an indispensable role in the transportation of chemical raw materials and wastewater treatment. A chemical company uses submersible pumps with corrosionresistant materials and special sealing technology to effectively solve the problems of medium leakage and equipment corrosion, and ensure the continuity and safety of production.

In the field of environmental protection, industrial submersible pumps are widely used in sewage treatment, river dredging and other projects. In the sewage treatment plant, the submersible pump lifts the sewage to the treatment equipment for purification; when the river is dredged, the silt at the bottom of the river can be pumped out to improve the water quality and ecological environment of the river. According to the project manager of an environmental protection engineering company, "The efficient operation of industrial submersible pumps enables us to complete environmental protection projects faster and better, and contribute to improving environmental quality."

In addition, in the construction, oil extraction and other industries, industrial submersible pumps are also widely used in foundation pit drainage, crude oil transportation and other links.

Industry experts pointed out that with the continuous advancement of industrial technology and the increasing requirements of various industries for equipment performance, industrial submersible pumps will develop in the direction of intelligence, high efficiency and energy saving, corrosion resistance, wear resistance, etc., and the application areas will be further broadened, providing strong support for the development of more industries.