Pump Shaft Seal

Simple structure: Sealing is achieved by compressing the packing, which is easy to maintain and low cost.

Reliant on shaft seal water: Continuous injection of pressurized water is required to prevent medium leakage, suitable for the last stage of multi-stage series pumps.

Applicable scenarios: Suitable for working conditions where sealing requirements are not high and medium dilution is allowed.

The shaft seal of a slurry pump is mainly used to prevent leakage of the conveying medium. Common structures include packing seal, auxiliary impeller seal and mechanical seal.

Packing seal

The seal is achieved by using compressed packing (packing), which has a simple structure and low cost, but has a large leakage and requires regular maintenance and replacement.

Auxiliary impeller seal

The centrifugal force generated by the auxiliary impeller balances the axial pressure and reduces medium leakage. It is suitable for high concentration and high pressure conditions, but the structure is complex and maintenance is difficult.

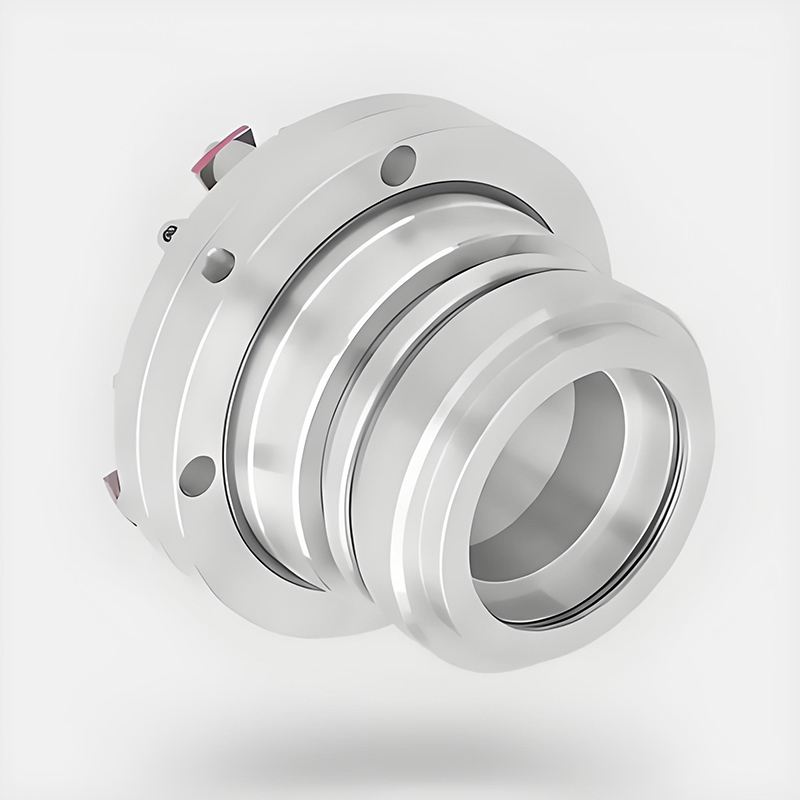

Mechanical seal

The end face sealing technology is used, which has small leakage and long service life, but the installation accuracy requirements are high, and it is suitable for corrosive and abrasive media.

The shaft seal configurations of different models of slurry pumps are different. For example, the AH type slurry pump provides three shaft seal options (packing, auxiliary impeller, mechanical seal), while the submersible slurry pump (such as 200SV-SP) adopts a shaft seal-free design and achieves sealing by immersion in liquid.