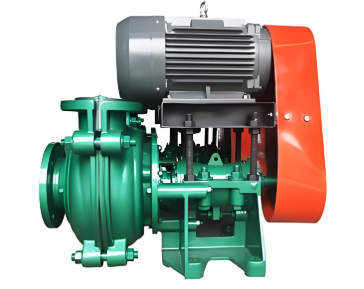

High Quality Mining Slurry Pump

1. Strong wear resistance

The slurry pump uses wear-resistant materials such as high chromium alloy and rubber lining, and can handle media with a solid particle concentration of up to 60% (according to the data of the Industrial Pump Design Manual). For example, the 150ZJ slurry pump used in a mine has a wear loss of only 3mm after 8000 hours of continuous operation, and its life is more than twice that of an ordinary pump.

2. Efficient conveying capacity

By optimizing the impeller and flow channel design, the efficiency of the slurry pump can reach 70%-85% (International Hydraulic Association standard). A metallurgical plant uses a 200QVSP pump to convey slurry, with a flow rate of 1200m³/h and a 18% reduction in energy consumption.

1. Definition and working principle

Definition: Slurry pump refers to a pump used to transport a mixture of solid particles containing slag and water. In principle, slurry pump is a type of centrifugal pump.

Working principle: When the impeller rotates rapidly, the blades of the impeller cause the slurry to rotate rapidly. The rotating slurry flies out of the impeller under the action of centrifugal force. After the liquid in the pump cavity is thrown out, a vacuum zone is formed in the center of the impeller. The slurry is pressed into the feed pipe through the pipe network under the action of atmospheric pressure or water pressure. In this way, continuous feeding can be achieved by circulating continuously, thereby achieving the head and flow required by the working condition design.

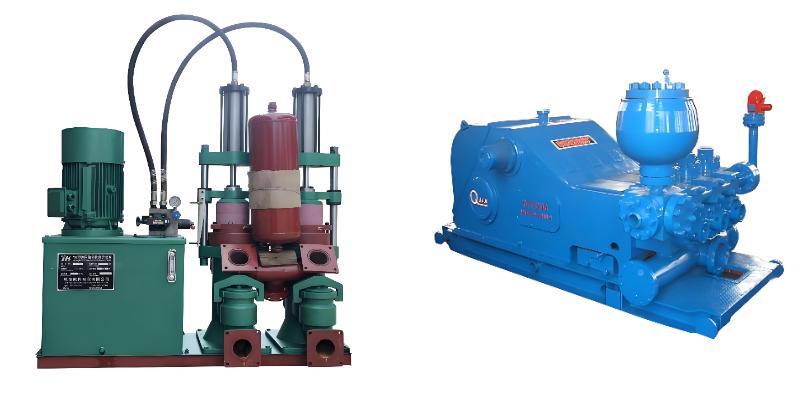

3. Structure and composition

The basic structure of the slurry pump consists of impeller, pump casing (pump body), shaft, bearing, bracket, shaft seal and other parts. The power is generally connected to the motor, which can be directly connected by a coupling, or connected by a belt or pulley.

Mining industry: used to transport slurry containing abrasive solid particles during the ore dressing process.

Power industry: mainly used in hydraulic ash removal systems of thermal power plants.

Metallurgical industry: transport slurry from systems such as blast furnace gas washing water, continuous casting turbid water and steel rolling turbid water.

Chemical industry: transport some corrosive slurries containing crystals.

Environmental protection industry: used for environmental protection projects such as river dredging and sewage treatment.

Seawater sand selection field: In the seawater sand selection process, slurry pumps are also called gravel pumps or dredging pumps.