SlurryPump Shaft Seal

Packing shaft seal

Applicable scenarios: Simple structure, easy maintenance, suitable for reverse flow installation.

Advantages: Economical and easy to maintain.

Disadvantages: Requires the use of shaft seal water, resulting in significant leakage and power loss

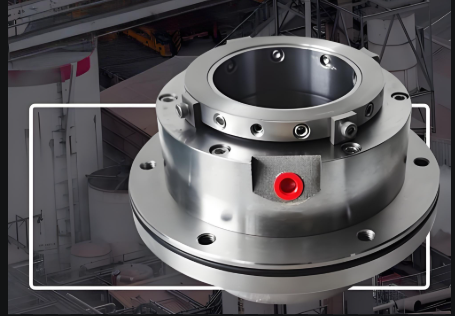

mechanical seal

Applicable scenarios: Suitable for highly corrosive, granular media, or high-precision sealing requirements.

Advantages: Good sealing effect, small leakage, long service life.

Disadvantages: High cost, complex installation and maintenance.

The main function of the slurry pump shaft seal is to prevent liquid leakage and air from entering the pump, while also preventing solid particles from entering the pump, ensuring the normal operation and sealing performance of the pump.

Specific function

Prevent liquid leakage

By using a sealing device, the liquid inside the pump is prevented from leaking from the shaft seal, avoiding liquid loss that may cause a decrease in pump efficiency or pollution of the working environment.

Prevent air from entering

The sealing structure can prevent external air from entering the pump, maintain stable pressure inside the pump, and prevent the performance of the pump from being affected by cavitation or pressure fluctuations.

Prevent solid particles from entering

The shaft seal needs to have wear resistance to prevent solid particles in the slurry from entering the pump and causing equipment damage or seal failure.

Common sealing forms

Packing sealing: Sealing is achieved through the soft and hard running in between the packing and the shaft sleeve, and shaft sealing water (pressure ≥ 1.5 times the outlet pressure) needs to be added

Secondary impeller seal: using the pressure head generated by the secondary impeller to resist liquid leakage, suitable for working conditions with backflow pressure ≤ 15% outlet pressure

Mechanical seal: Sealing is achieved through friction between the dynamic and static rings, and is divided into types such as non water injection (with a lifespan of about 4000 hours), water injection external flushing (with a lifespan of about 6000 hours), etc