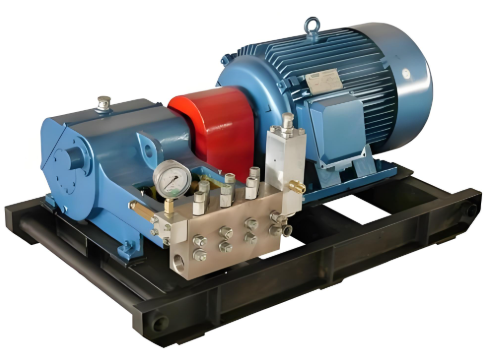

Desulfurization Plunger Pump

Corrosion Resistance: The piston pump's sealing components (such as the plunger and cylinder bore) are manufactured using high-precision machining techniques, ensuring a tight fit and effectively isolating the pump from corrosive media. Suitable for use in corrosive environments such as acidic wastewater, however, caution is advised: chloride ion concentrations exceeding 5000 ppm may cause corrosion of the coating, necessitating regular replacement of the sealing components.

Flue gas desulfurization (FGD) plunger pumps are key equipment used in wet FGD systems. They are primarily used to transport slurries containing solid particles (such as limestone slurries and gypsum slurries). They feature wear resistance, corrosion resistance, and reliable operation.

Operating Principle

A plunger pump uses the reciprocating motion of the plunger rod to change the chamber volume, generating a pressure differential to transport liquid.

When the plunger moves inward, the chamber volume decreases, pushing liquid out; when it moves outward, liquid is drawn in. This reciprocating motion enables the pump to operate continuously, making it suitable for transporting high-pressure, high-viscosity media.

Key Features

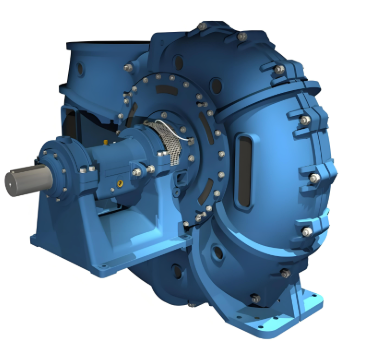

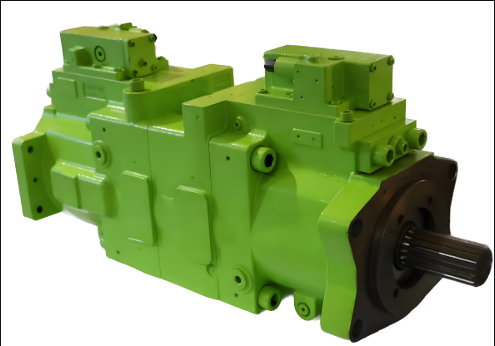

Wear-Resistant Material: Flow-through components are constructed of all-metal, wear-resistant materials (such as chromium-nickel alloy) to withstand the abrasive conditions caused by solid particles in the slurry, achieving a dynamic wear resistance of 0.008-0.08 mm/year.

Optimized Structure: The impeller, volute, and other components utilize a solid-liquid two-phase flow hydraulic model, providing enhanced cavitation resistance and 3%-5% higher efficiency than non-metallic pumps.

Seal Design: A cartridge mechanical seal and back-vane structure effectively prevent solid particles from entering the seal chamber, extending service life.

Easy Maintenance: The rotor components can be removed from the motor for maintenance without disassembling inlet and outlet pipelines or the motor, simplifying maintenance.

Applicable Applications: Primarily used for slurry circulation in absorption towers, limestone slurry transfer, and gypsum slurry discharge in power plant desulfurization systems. It can handle highly corrosive slurries with a pH of 2.5-13 and a chloride ion concentration ≤60,000 ppm.