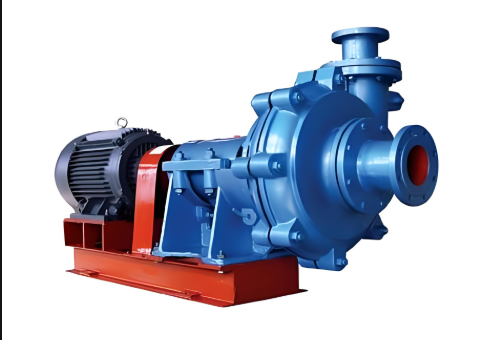

Centrifugal Slurry Pump

Material and Wear Resistance: Made of natural rubber, it offers excellent corrosion resistance and is particularly suitable for conveying slurries free of sharp edges and fine powdery impurities (such as iron ore concentrate). However, it is less scratch-resistant and may harden in the presence of alkali.

Low head, small flow area: can transport highly abrasive slurries

The AHR slurry pump (also stated as the AHR slurry pump) is a cantilevered horizontal centrifugal pump in specific used for conveying pretty abrasive, noticeably founded slurries. It is appropriate for use in industries such as metallurgy, mining, coal mining, and electrical energy generation.

Core Features

Material: Wetted elements are made of high-chromium wear-resistant alloy. Shaft seals are on hand with a packing seal, impeller seal, or mechanical seal.

Design: Double-casing construction, with impellers, jackets, and exceptional elements developed of wear-resistant alloy. Multi-stage cascade operation is possible.

Applications: Conveys corrosive or exceptionally headquartered slurries containing tightly closed particles (such as pulverized coal and slag), on the whole extremely good for conveying fine-grained slurries with small, non-sharp particles.

Technical Parameters

Flow Rate Range: Typically 50-1000 cubic meters per hour (specific parameters differ relying on mannequin selection, e.g., the 4/3C-AHR mannequin has a go with the go with the glide price fluctuate of 22-700 cubic meters per hour).

Lift Range: Up to seven-hundred meters (e.g., 80-700 meters for the 4/3C-AHR model).

Speed Range: Common speeds are 400-3400 rpm (e.g., 800-1800 rpm for the 4/3C-AHR model).

Accessories and Maintenance

Consumable Parts: Includes impeller, casing, front/rear shield plates, etc. (metal or rubber).

Common Faults: Excessive shaft electrical energy and bearing overheating are generally precipitated through overtightening the packing gland, unsuitable grease, or overseas locations be counted getting into the bearing. These can also additionally in addition require adjusting the packing gland or altering the bearing.