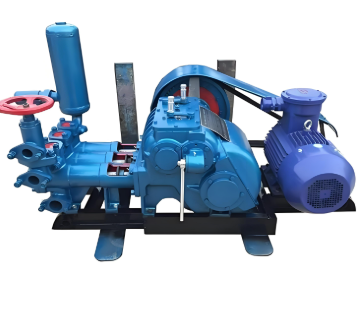

The sewage slurry pump is a key mechanical equipment for conveying mud, water and other flushing fluids to the borehole in drilling projects. It is a component of drilling equipment and is widely used in mining, petroleum, environmental protection, water conservancy projects and agricultural drainage [1-2]. Its main functions are to cool the drill bit, remove rock debris and maintain the stability of the borehole. It can also be used in sewage treatment, municipal sewage discharge, river dredging and other scenarios [2-3]. The pump adopts a single-stage single-suction vertical centrifugal pump design.![1756300085406317.jpg]() The core components include volute, impeller, pump seat, etc. The impeller adopts a semi-enclosed structure with three single arc curved blades to improve wear resistance [2-3]. The pump body material is mostly corrosion-resistant pig iron or malleable cast iron, and supports vertical or inclined installation. The performance parameters cover flow rate 40-180m³/h, head 8-80m, speed up to 3600r/min, and motor power 1.5-22kW. According to the structure, it is divided into single-cylinder, double-cylinder and triple-cylinder types. It has two working modes, single-acting and double-acting. The technical indicators are adjusted according to the borehole diameter, depth and working conditions. In the commonly used positive circulation drilling, it is to send the surface flushing medium - clean water, mud or polymer flushing liquid under a certain pressure through a high-pressure hose, a faucet and the center hole of the drill pipe column directly to the bottom of the drill bit to achieve the purpose of cooling the drill bit, removing the cut rock chips and transporting them to the surface. The commonly used mud pump is piston or plunger type. The crankshaft of the pump is driven by the power machine to rotate, and the crankshaft drives the piston or plunger to reciprocate in the pump cylinder through the crosshead. Under the alternating action of the suction and discharge valves, the purpose of pressurizing and circulating the flushing liquid is achieved. Classification of sewage mud pumps Mud pumps are divided into single-acting and double-acting types. The single-acting type only completes one suction and drainage action in one cycle of the piston reciprocating motion. The double-acting type completes two suction and drainage actions per reciprocating. If classified by the number of cylinders of the pump, there are three types: single-cylinder, double-cylinder and triple-cylinder. Performance of sewage mud pumps The two main parameters of sewage mud pump performance are displacement and pressure. Displacement is calculated as a number of liters per minute, which is related to the borehole diameter and the required return speed of the flushing fluid from the bottom of the hole, that is, the larger the borehole diameter, the larger the required displacement. The return speed of the flushing fluid is required to flush the rock chips and rock powder cut by the drill bit away from the bottom of the hole in time and reliably carry them to the surface. When drilling geological cores, the general return speed is about 0.4 to 1.0 meters per minute. The pressure of the pump depends on the depth of the borehole, the resistance of the channel through which the flushing fluid passes, and the properties of the flushing fluid being transported. The deeper the borehole, the greater the pipeline resistance and the higher the pressure required. With the change of borehole diameter and depth, the displacement of the pump is required to be adjusted at any time. A gearbox is provided in the pump mechanism or its speed is adjusted by a hydraulic motor to achieve the purpose of changing the displacement. In order to accurately grasp the changes in pump pressure and displacement, flow meters and pressure gauges should be installed on the mud pump to enable drilling personnel to understand the operation of the pump at any time. At the same time, the pressure changes can be used to determine whether the conditions in the hole are normal to prevent accidents in the hole.

The core components include volute, impeller, pump seat, etc. The impeller adopts a semi-enclosed structure with three single arc curved blades to improve wear resistance [2-3]. The pump body material is mostly corrosion-resistant pig iron or malleable cast iron, and supports vertical or inclined installation. The performance parameters cover flow rate 40-180m³/h, head 8-80m, speed up to 3600r/min, and motor power 1.5-22kW. According to the structure, it is divided into single-cylinder, double-cylinder and triple-cylinder types. It has two working modes, single-acting and double-acting. The technical indicators are adjusted according to the borehole diameter, depth and working conditions. In the commonly used positive circulation drilling, it is to send the surface flushing medium - clean water, mud or polymer flushing liquid under a certain pressure through a high-pressure hose, a faucet and the center hole of the drill pipe column directly to the bottom of the drill bit to achieve the purpose of cooling the drill bit, removing the cut rock chips and transporting them to the surface. The commonly used mud pump is piston or plunger type. The crankshaft of the pump is driven by the power machine to rotate, and the crankshaft drives the piston or plunger to reciprocate in the pump cylinder through the crosshead. Under the alternating action of the suction and discharge valves, the purpose of pressurizing and circulating the flushing liquid is achieved. Classification of sewage mud pumps Mud pumps are divided into single-acting and double-acting types. The single-acting type only completes one suction and drainage action in one cycle of the piston reciprocating motion. The double-acting type completes two suction and drainage actions per reciprocating. If classified by the number of cylinders of the pump, there are three types: single-cylinder, double-cylinder and triple-cylinder. Performance of sewage mud pumps The two main parameters of sewage mud pump performance are displacement and pressure. Displacement is calculated as a number of liters per minute, which is related to the borehole diameter and the required return speed of the flushing fluid from the bottom of the hole, that is, the larger the borehole diameter, the larger the required displacement. The return speed of the flushing fluid is required to flush the rock chips and rock powder cut by the drill bit away from the bottom of the hole in time and reliably carry them to the surface. When drilling geological cores, the general return speed is about 0.4 to 1.0 meters per minute. The pressure of the pump depends on the depth of the borehole, the resistance of the channel through which the flushing fluid passes, and the properties of the flushing fluid being transported. The deeper the borehole, the greater the pipeline resistance and the higher the pressure required. With the change of borehole diameter and depth, the displacement of the pump is required to be adjusted at any time. A gearbox is provided in the pump mechanism or its speed is adjusted by a hydraulic motor to achieve the purpose of changing the displacement. In order to accurately grasp the changes in pump pressure and displacement, flow meters and pressure gauges should be installed on the mud pump to enable drilling personnel to understand the operation of the pump at any time. At the same time, the pressure changes can be used to determine whether the conditions in the hole are normal to prevent accidents in the hole.

![Portable Mud Pump Portable Mud Pump]()