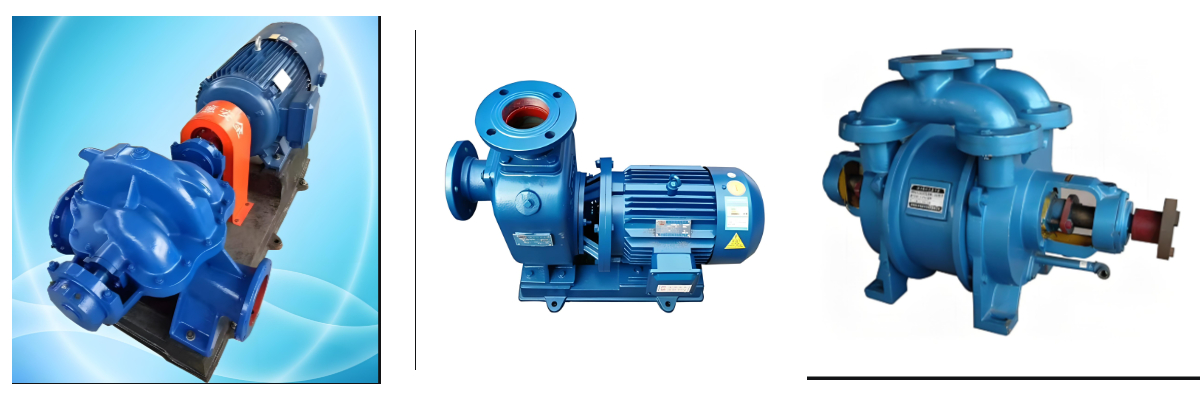

Large Flow Split Pump

Revolutionary Structural Design Advantages

1. Innovative Horizontal Split Case Design

The pump body is split horizontally along the axis, eliminating the need to disassemble inlet and outlet piping.

For maintenance, simply open the pump cover to access internal components.

- Typical maintenance time is over 70% shorter than end-suction pumps.

2. Double-Suction Symmetrical Flow System

- Bidirectional water inlet design increases flow rate by 35-50% (under the same power conditions).

- Patented impeller hydraulic model achieves an industry-leading efficiency of 92%.

- Automatic axial force balancing system extends bearing life by three times.

The split-case double suction pump is a horizontally split double suction centrifugal pump with the following core features:

1. Innovative split structure

The pump body is horizontally split along the axis (split design)

The inlet and outlet flanges are integrated in the lower half of the pump body

The upper cover can be disassembled separately (no need to dismantle the pipeline for maintenance)

2. Double suction impeller system

Symmetrical double suction impeller design (bidirectional water intake)

The impeller is optimized by CFD of three-dimensional flow

Axial force self-balancing structure (no thrust bearing design)

Six core advantages

1.Revolutionary maintenance design

Unique quick-opening pump cover (50% fewer bolts)

Built-in guide rail positioning system (reset accuracy 0.05mm)

Visual observation window (real-time monitoring of operating status)

2. Military-grade reliability

Bearing life exceeds 80,000 hours (three times the industry standard)

Safety factor of key components ≥ 2.5

Passed 1 million times fatigue test

3. Intelligent operation and maintenance system

Optional 5G intelligent monitoring terminal

Supports digital twin fault prediction

Remote diagnosis response time < 15 minutes