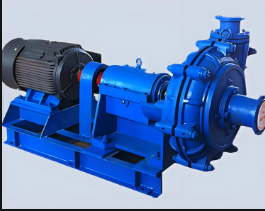

Slurry Pump For Mining

High head, high flow area: Suitable for conveying lightly abrasive slurries (such as coal washing wastewater);

Corrosive media: Excellent adaptability to acidic environments.

Structural Features:

Cantilever structure, lightweight and compact;

Replaceable rubber lining, easy maintenance;

Impeller made of high-chromium wear-resistant alloy, durable and wear-resistant.

The AHR slurry pump (also known as the AHR slurry pump) is a cantilevered horizontal centrifugal pump primarily used for conveying highly abrasive, highly concentrated slurries. It is suitable for use in industries such as metallurgy, mining, coal mining, and power generation.

Core Features

Material: Wetted parts are made of high-chromium wear-resistant alloy. Shaft seals are available with a packing seal, impeller seal, or mechanical seal.

Design: Double-casing construction, with impellers, jackets, and other components constructed of wear-resistant alloy. Multi-stage cascade operation is possible.

Applications: Conveys corrosive or highly concentrated slurries containing solid particles (such as pulverized coal and slag), particularly suitable for conveying fine-grained slurries with small, non-sharp particles.

Technical Parameters

Flow Rate Range: Typically 50-1000 cubic meters per hour (specific parameters vary depending on model selection, e.g., the 4/3C-AHR model has a flow rate range of 22-700 cubic meters per hour). Head Range: Up to 700 meters (e.g., 80-700 meters for the 4/3C-AHR model).

Speed Range: Common speeds are 400-3400 rpm (e.g., 800-1800 rpm for the 4/3C-AHR model).

Accessories and Maintenance

Consumable Parts: Includes impeller, casing, front/rear guards, etc. (metal or rubber).

Common Faults: Excessive shaft power and bearing overheating are often caused by overtightening the packing gland, improper grease, or foreign matter entering the bearing. Adjusting the packing gland or replacing the bearings may be necessary