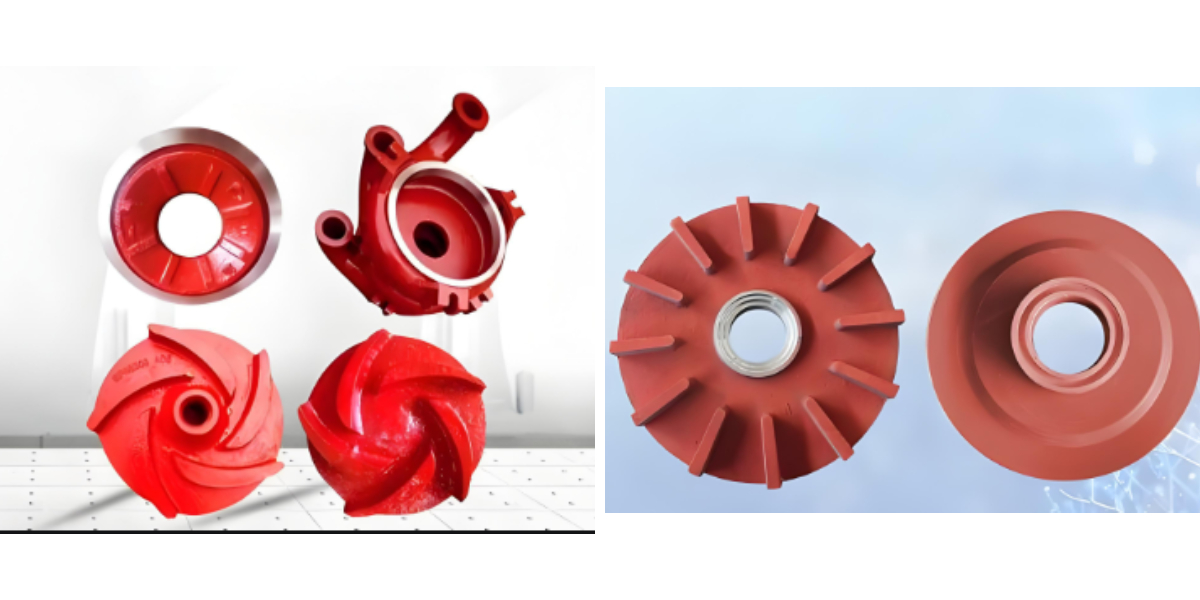

Polyurethane Wear-Resistant Pump Jacket

Extending pump life: The sleeve acts as a "sacrificial part," carrying first, defending the pump casing and lowering standard substitute frequency.

Adaptable to complicated working conditions, customizable thickness and cloth are accessible (e.g., rubber sleeves for media containing coarse particles, metallic sleeves for high-temperature and high-pressure applications).

The slurry pump jacket (also identified as the pump casing liner or put on liner) is a core wear-resistant aspect of a slurry pump. Installed internal the pump casing, it protects the pump physique from damage triggered thru rather concentrated, abrasive slurries. Its diagram except extend impacts the pump's provider life, jogging efficiency, and safety costs.

1. Functions of the Slurry Pump Jacket

Wear Protection: Withstands high-speed have an affect on from steady particles (such as ore, coal slag, and sand and gravel) to prevent put on on the pump casing.

Corrosion Resistance: For acidic and alkaline media (such as mine tailings and chemical wastewater), corrosion-resistant resources (such as rubber and high-chromium alloy) are used.

Modular Replacement: The jacket is a "wearing part" and can be modified for my phase when worn, reducing customary maintenance costs.

Flow Optimization: Maintains easy go with the go with the flow paths internal the pump, reduces turbulence, and improves pumping efficiency.

High-chromium alloy (Cr26/Cr28) affords immoderate hardness (HRC 58-65), top notch put on resistance, and realistic cost. 6-12 months for high-abrasion scenes such as mining slurry and sand and gravel transportation

Rubber bushings (natural/synthetic) Good elasticity, resistance to inclined acids and inclined alkalis, soak up shock and vibration, then again terrible temperature resistance (≤80℃). Sewage containing first-class particles, tailings slurry. 3-8 months

Ceramic composite (Al₂O₃/SiC) Super hard, resistant to sturdy acids and alkalis, then again brittle and prone impact resistance. High-precision scenes such as chemical slurry and electrical energy plant desulfurization. 12-24 months

Polyurethane (PU) Wear resistance is shut to that of rubber, with greater oil resistance, terrific for traditional disassembly conditions. Occasions with oily media or requiring fast replacement. 4-10 months

3. Structural layout of the sheath

(1) Split liner

- Large slurry pumps use a mixture of extra than one liner plates (such as greater and limit reduce up type, fan-shaped block type). After close by wear, fully the damaged part is replaced, saving costs.

Advantages: Reduce downtime and minimize spare elements inventory pressure.

(2) Adjustable Thickness - Thickened jacket format (e.g., 30-50mm) extends service life and is in particular fantastic for high-concentration (solid content material cloth ≥40%) or large particle (e.g., Φ20mm and above) applications. (3) Optimized Flow Path - Smooth interior wall layout or spiral drift path reduces turbulence and eddy currents, reducing the hazard of localized wear.