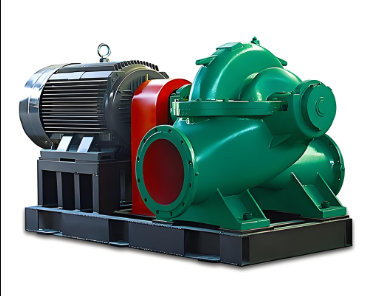

High-Efficiency Double-Suction Pump

Compact Structure: Beautiful appearance, excellent stability, and easy installation.

Smooth Operation: The optimized double-suction impeller minimizes axial force and features a blade profile with excellent hydraulic performance. Precision casting ensures an extremely smooth inner surface of the pump casing and impeller, resulting in excellent cavitation resistance and high efficiency.

A double-suction water pump is a high-efficiency, high-flow centrifugal pump with a double-sided water inlet design. It is widely used in municipal water supply, industrial circulation, agricultural irrigation, and other fields. The following is a detailed introduction to its structure, principles, advantages, selection, application, and maintenance.

1. Double-Suction Water Pump Structure

The core features of a double-suction water pump are its perfectly symmetrical dual suction inlets and horizontal split-case design. Its main components include:

Component Function Description

Water inlets from both sides of the double-suction impeller provide high flow rates and automatic axial force balance.

Pump Casing (Horizontal Split-Case): The pump body is split horizontally along the axis, allowing for easy access to the impeller and seals.

Bearing support supports the pump shaft, reducing vibration and extending service life.

Mechanical seals with packing seals prevent leakage and are suitable for various media.

Standard inlet and outlet flange connections facilitate piping installation.

Differences from single-suction pumps: Single-suction pumps have water inlet from only one side, resulting in lower flow rates and requiring additional equipment to balance axial forces.

2. Working Principle of a Double-Suction Water Pump

1. Inlet Phase: Liquid enters the impeller simultaneously from both sides of the pump body.

2. Centrifugal Supercharging: The impeller rotates at high speed, and the liquid is driven by centrifugal force to flow toward the outer edge of the impeller, converting kinetic energy into pressure energy.

3. Discharge Phase: The high-pressure liquid is collected by the volute and discharged from the outlet.

Axial Force Self-Balance: Symmetrical inlet pressure on both sides reduces bearing load and extends life.

3. Core Advantages of Double-Suction Pumps

High Flow: The double-suction structure increases flow by 30%-50% compared to single-suction pumps.

Suitable for water plants and large-scale irrigation.

High Efficiency: Low hydraulic loss, 3%-5% higher efficiency than single-suction pumps.

Suitable for industrial systems with high energy requirements.

Low Cavitation: Low inlet velocity and low NPSHr (Net Positive Net Suction Head Required).

Suitable for high-temperature water and easily vaporized media.

Long-life, self-balancing axial forces minimize bearing and seal wear.

Suitable for 24/7 continuous operation.

Horizontal split-case design allows for maintenance without disassembly.

Key industries such as chemical industry and electric power

4. Main application areas of double suction water pumps

(1) Municipal water supply

Waterworks main pump

Urban booster pump station

Fire water supply system

(2) Industrial circulation

Power plant cooling water circulation

Chemical plant process pump

Steel plant cooling system

(3) Agricultural irrigation

Reservoir/river water lifting

-Large farmland irrigation