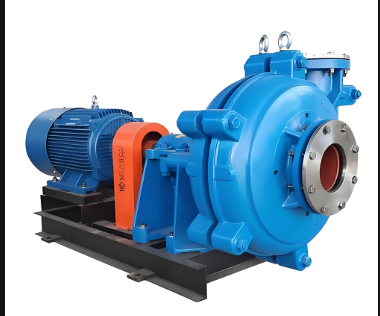

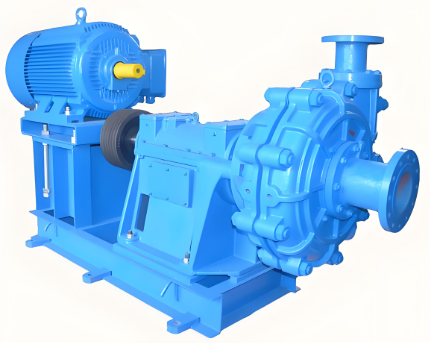

Horizontal Slurry Pump

Flexible installation adapts to various operating conditions.

Small footprint: Horizontal pumps typically take up less space than vertical pumps and are suitable for compact plant configurations.

Multiple drive options: Available with electric, diesel, and hydraulic motors to meet varying power requirements.

Adjustable inlet and outlet direction: Select models offer adjustable inlet and outlet directions, facilitating piping layout.

Low maintenance costs

Typical application areas

Mining industry: tailings transportation, ore dressing plant slurry pumping, concentrate dewatering.

Power industry: desulfurization slurry circulation in power plants, ash transportation.

Metallurgical industry: steelmaking sludge, aluminum plant red mud treatment.

Chemical industry: corrosive slurry, acid and alkali liquid transportation.

Dredging engineering: river dredging, port dredging, sand pumping operations.

Common classification methods

(1) Classification by material

Metal slurry pump: high chromium alloy, wear-resistant cast iron, suitable for high wear conditions.

Rubber lined slurry pump: corrosion-resistant, suitable for acidic and alkaline slurries.

(2) Classification by sealing type

Auxiliary impeller + packing seal: low cost, requires regular maintenance.

Mechanical seal: less leakage, long life, suitable for high-demand working conditions.

(3) Classification by drive mode

Electric motor drive: commonly used in fixed working conditions.

Diesel engine drive: occasions without power supply (such as field construction).