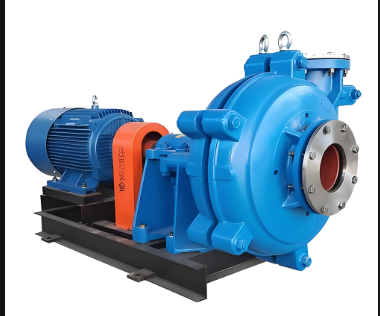

High Chromium Alloy Slurry Pump

First, in terms of structure, slurry pumps typically adopt a horizontal design, resulting in a compact overall layout and a small footprint. This makes them easy to install and deploy in a variety of workplaces, adapting well to both confined spaces and large industrial plants.

Secondly, the flow-through components of the slurry pump are made of excellent materials and are generally made of wear-resistant materials such as high-chromium cast iron and rubber. They can effectively resist the wear and impact of particles in the slurry, greatly extending the service life of the pump and reducing maintenance costs.

A horizontal slurry pump is a common type of slurry pump. Its core feature is the centrifugal force generated by the rotation of the impeller, which transports solid-liquid mixtures. It is widely used in mining, metallurgy, power generation, and other fields.

The following is a detailed description:

Structural Features

It utilizes a vertically split double-casing design with an axial inlet and a radial outlet. The pump supports 45° rotation and adjustment of the mounting angle to suit different operating conditions.

The flow path components typically utilize a cast iron body with a wear-resistant rubber liner. The metal or rubber liner can be replaced to extend service life.

Key Technologies

Bearing Assembly: A cylindrical design facilitates maintenance, supports grease lubrication, and features an adjustable clearance between the impeller and the front guard.

Shaft Seal: Available with a stuffing box, impeller seal, or mechanical seal.

Drive: Supports various drive options, including V-belts, flexible couplings, and gear reducers.