Slurry Pump Wear Plate

Wear Resistance

The protect plate is generally made of a high-chromium alloy (such as Cr26) with a hardness of ≥HRC60, successfully resisting put on from high-concentration stable particles and extending its carrier lifestyles by way of 3-5 instances in contrast to regular materials.

Sealing

It types a labyrinth-like hole seal with the impeller, lowering the hazard of slurry leakage. The lower back vane plan additionally efficaciously discharges backflow slurry, enhancing volumetric efficiency.

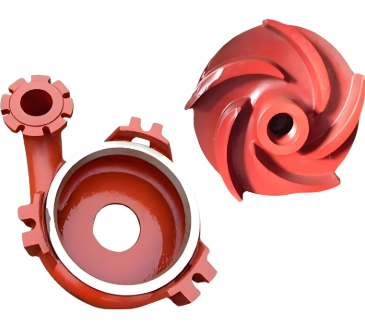

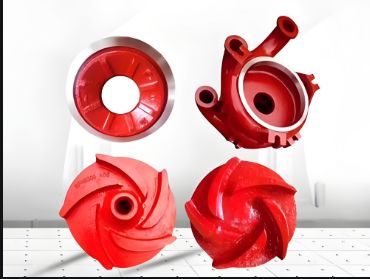

The slurry pump guard plate is the core overcurrent component of the slurry pump, which, together with the sheath and impeller, constitutes the internal structure of the pump. Its function is to cooperate with the sheath to form a semi closed flow channel, allowing the slurry to flow in a specific space while withstanding the impact of the slurry.

structure and classification

Guard plates are usually divided into front guard plates and rear guard plates (some models only have rear guard plates). The front guard plate directly bears fluid impact, and the main force bearing part is located at the water outlet; The rear guard plate is connected to the impeller and is responsible for guiding and sealing the slurry.

materials and processes

The material of the protective plate is mostly KMTBCr26 (wear-resistant cast steel), Cr15Mo3 or rubber, among which KMTBCr26 is widely used due to its high wear resistance. The casting process needs to address defects such as shrinkage and porosity at the outlet, such as increasing the number of top risers, optimizing the pouring temperature (1370-1390 ℃), and improving the sand baking process to improve quality.

Installation and maintenance

The installation of the protective plate needs to form a reasonable gap with the impeller and sheath to ensure sealing and overcurrent efficiency. Daily maintenance requires checking for wear and timely replacement to avoid shaft seal leakage or damage to overcurrent components.