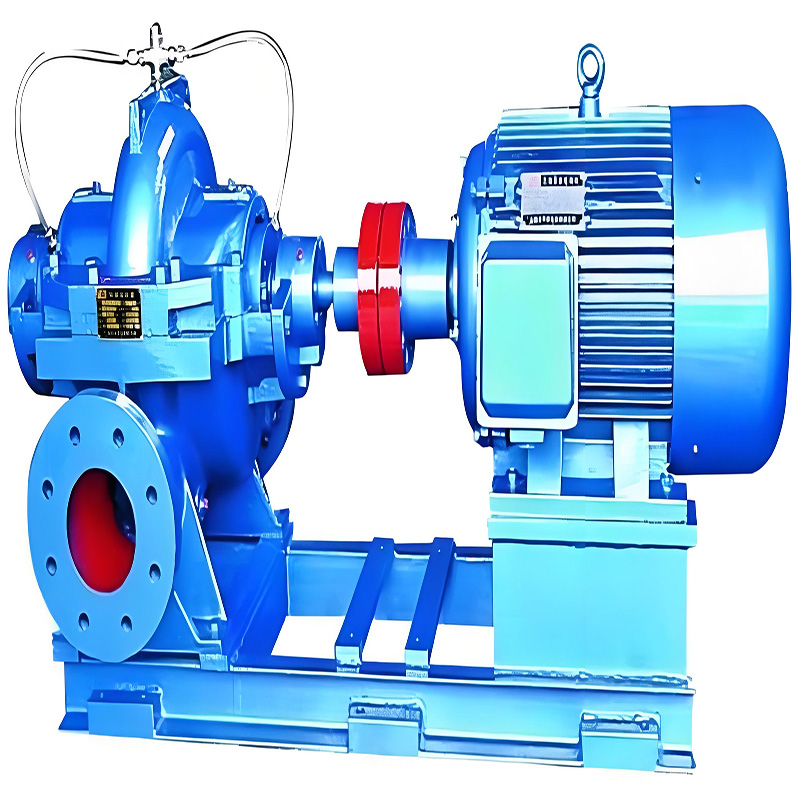

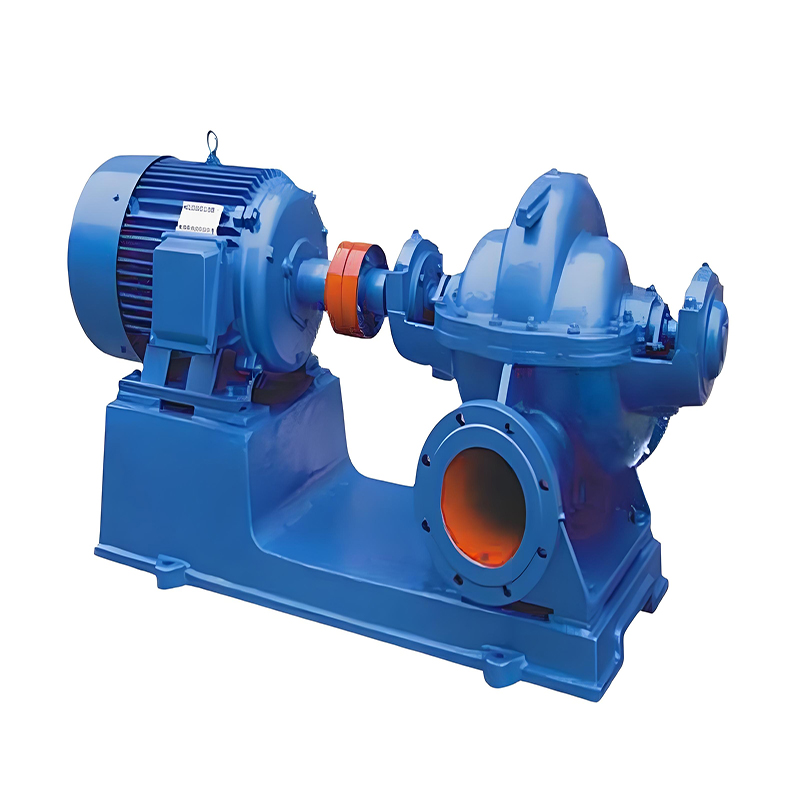

Single Casing Pump Cheap

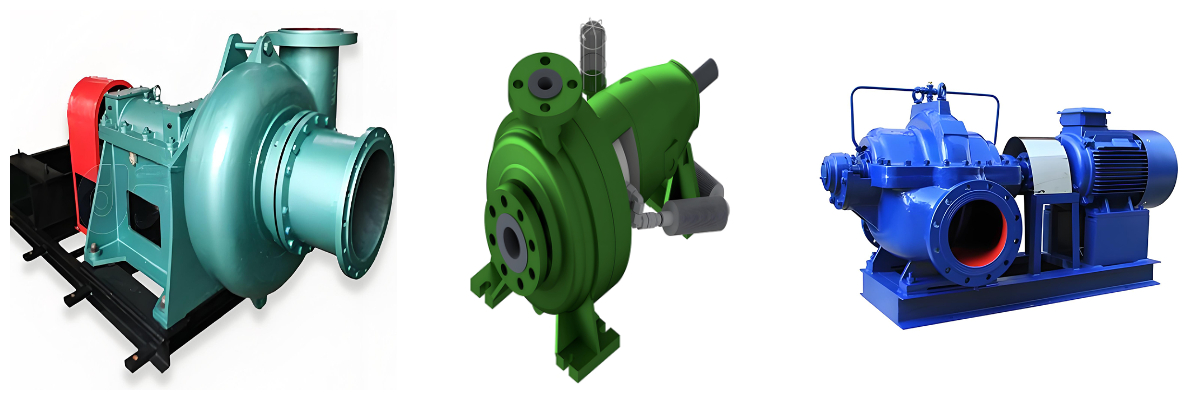

GYD series solid-liquid single shell slurry pump

Structural features: GYD series solid-liquid single shell slurry pump adopts a single shell structure, suitable for handling high-concentration solid-liquid mixtures.

Application areas: Widely used in mining, metallurgy, power and other industries, suitable for conveying ore slurry, coal slurry, tailings, etc.

ZJD single shell slurry pump

Structural features: ZJD single shell slurry pump adopts a single shell design, the pump body is made of ASTM A532 Cr27 high chromium cast iron, the impeller is a closed 6-blade, and the sealing system adopts a double-end mechanical seal plus a flushing device.

A single-shell pump (or single-shell slurry pump) is an industrial pump specially used for conveying high-concentration, highly abrasive solid-liquid mixed slurries. Its core feature is the use of a single-layer pump shell structure, which is simpler in structure and easier to maintain than a double-shell pump. The following is a systematic introduction from the perspectives of structure, application, performance, and manufacturer.

I. Basic structure and working principle

1. Pump shell design

Single-layer pump shell structure, the outer shell is mostly made of ductile iron or cast steel, and the inner lining is made of high-chromium alloy wear-resistant materials (such as high-chromium cast iron), which has strong abrasion resistance.

The flow-through parts (impeller, volute, etc.) are optimized according to the solid-liquid two-phase flow theory to reduce eddy current and impact losses, and reduce wear and vibration.

2. Sealing form

Supports two shaft sealing methods: auxiliary impeller + packing seal (power pressure reduction and leakage prevention) or mechanical seal to meet different working conditions.

3. Installation flexibility

The outlet direction can be installed in 8 angles at 45° intervals to adapt to complex pipeline layouts

2. Application fields and conveying media

-Applicable industries: power (ash removal in power plants), metallurgy, mining (tailings transportation), coal (coal slime heavy medium selection), chemicals and building materials, etc.

Processing media: abrasive slurries containing solid particles, such as ore slurry, ash slurry, coal slime, etc., with a maximum concentration of: 45% ash slurry, 60% ore slurry.

Special working conditions: support series operation to meet high lift requirements, such as long-distance pipeline transportation.