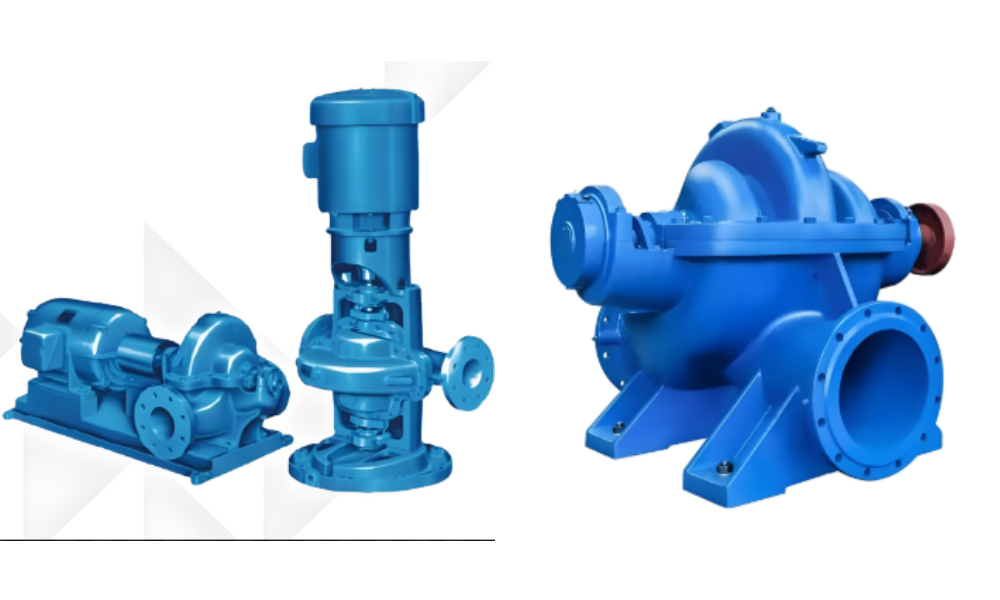

Double Suction Split Pump Price

Double suction split pump has the following features:

Large flow rate: Double suction split pump is equivalent to two single suction impellers of the same diameter working at the same time, and the flow rate can be doubled under the same impeller outer diameter

Axial force self-balancing: The impeller structure of the double suction split pump is symmetrical, there is no axial force, the operation is relatively stable, the burden on the bearing is reduced, and the bearing life is extended

High efficiency and energy saving: Its unique structural design makes the fluid flow in the pump smoother, reduces energy loss, and reduces energy consumption

Easy maintenance: The horizontal center opening design of the pump casing is convenient for inspection and maintenance. The inlet and outlet are in the same direction and perpendicular to the pump shaft, which is conducive to the layout and installation of the pump and the inlet and outlet pipes

Wide application: It is suitable for various occasions requiring large flow and low head, such as urban water supply, farmland irrigation, power station circulating water and other fields

Economical and durable: Although the initial investment may be slightly higher, its efficient operation performance and long-term stability make it more economical in long-term use, and it can maintain stable performance even in harsh working environments

It is a centrifugal pump with high head and large flow rate, and is widely used in engineering. Its impeller is composed of two back-to-back impellers, and the water flowing out of the impellers converges into a volute. This design makes the double-suction pump equivalent to two single-suction impellers of the same diameter working at the same time, so that the flow rate can be doubled under the same impeller outer diameter. Structural features The main structural components of the double-suction split pump include pump body, pump cover, impeller, shaft, double-suction sealing ring, sleeve, bearing, etc. The pump body and pump cover constitute the working room of the impeller. The impeller is statically balanced and fixed with sleeves and sleeve nuts on both sides. Its axial position can be adjusted by sleeve nuts, and the axial force of the impeller is balanced by the symmetrical arrangement of its blades. The pump shaft is supported by two single-row radial ball bearings, which are installed in the bearing bodies at both ends of the pump body and lubricated with grease. Double suction seal ring is used to reduce the water leakage from the pump pressure chamber back to the suction chamber. Application field Double suction split pump is suitable for various occasions requiring large flow and high head, such as urban and industrial water supply and drainage, agricultural irrigation and drainage, high-rise water supply, building fire protection, central air conditioning water circulation, circulating water supply in engineering systems, cooling water circulation, boiler water supply, etc. It is particularly suitable for conveying clean water or liquids with physical and chemical properties similar to water, and the medium temperature range is -20℃ to 80℃.

Models and parameters

Common double-suction split pump models include S-type single-stage double-suction centrifugal pump, DK-type multi-stage double-suction split-case pump, GS-type high-efficiency energy-saving double-suction pump, etc. For example, the flow range of DK-type multi-stage double-suction split-case pump is 18~1368m³/h, and the head can reach 100~360m. It is suitable for conveying clean water or similar liquids, and the applicable temperature is -20℃ to 80℃