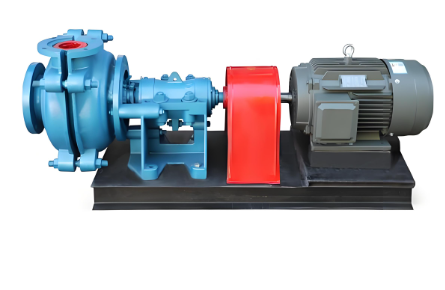

Tailings Treatment AH Slurry Pumps

1. Excellent Wear Resistance

High-Chromium Alloy Material: AH slurry pumps utilize high-chromium wear-resistant alloys (Cr26, Cr28) for key components (such as the impeller, guard plate, and pump casing). This high hardness and excellent wear resistance make it suitable for conveying high-concentration, highly abrasive slurries.

Rubber Lining Option: Select models feature an optional wear-resistant rubber lining, suitable for conveying corrosive slurries and extending service life.

The AH slurry pump (also known as the AH slurry pump) is a heavy-duty, highly wear-resistant centrifugal pump designed specifically for conveying highly concentrated, highly abrasive, and highly corrosive slurries. It is widely used in mining, metallurgy, power generation, chemical engineering, dredging, and other industries, and is suitable for tailings conveying, slurry circulation, desulfurization gypsum slurry, and slag treatment.

II. Main Application Areas

Mining tailings transportation, slurry circulation, concentrate transportation

Metallurgy: slag treatment, alumina slurry transportation

Power plant desulfurization gypsum slurry transportation

Chemical industry: corrosive slurries and highly abrasive media transportation

Dredging: River desilting and sediment transportation

Building materials: Cement slurry and coal slurry transportation

AH slurry pumps vs. conventional slurry pumps

Wear resistance: High chromium alloy/rubber lining for longer life | Conventional materials, rapid wear |

Applicable concentration: 60%-70% solids content | Generally ≤50% |

Maintenance cost: Modular design for easy replacement | Complex maintenance and long downtime |

Application industries: High-wear environments such as mining and metallurgy | General industrial slurry transportation |