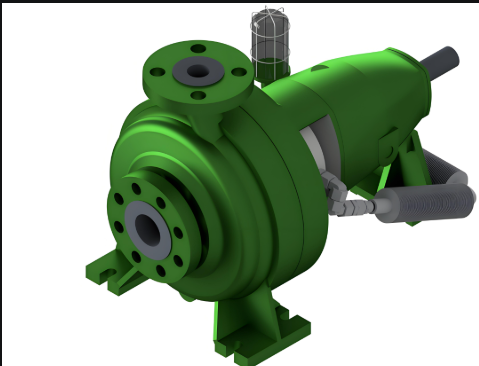

Single-Casing Impeller Pump

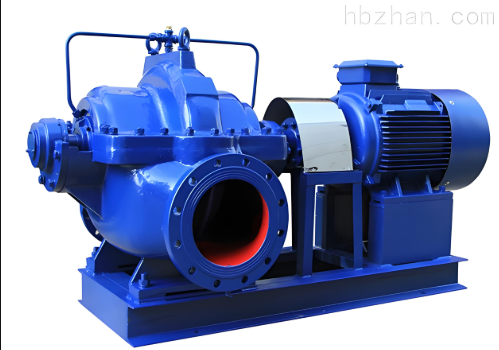

Structural and Cost Advantages

Single-impeller pumps offer a simple structure and fewer components, significantly reducing manufacturing and maintenance costs, making them suitable for budget-constrained applications.

Head Performance Advantages

The single-impeller design provides high head capacity, suitable for long-distance transport or high-pressure applications (such as high-rise building water supply). Dual-impeller pumps, on the other hand, are more suitable for high-flow applications with lower head.

The impeller single-casing pump (also known as a single-stage, single-suction centrifugal pump) is a common type of centrifugal pump with the following features:

Structural Features

It employs an axial suction structure, with the impeller mounted directly on the end of the drive shaft. An optimized radial flow channel reduces hydraulic losses. Its core components include impellers, a pump casing, an inlet, and an outlet, resulting in a relatively simple structure.

Functions and Applications

It is primarily used in municipal water supply, agricultural irrigation, industrial liquid transportation, and water circulation systems, offering low to medium heads and high flow rates. For example, the CMR series, with its open impeller design, can handle non-corrosive liquids containing suspended solids and is suitable for applications such as rainwater drainage and river and lake water intake.

Performance Parameters

Voltage: Supports single-phase 230V and three-phase 230/400V voltages

Protection Level: Meets IP44 standards

Insulation Class: Class F

Motor Type: Asynchronous enclosed motor with overheating and overload protection devices

This type of pump excels in applications requiring stable flow output due to its compact design and low maintenance costs.