Rolly Slurry Tanker

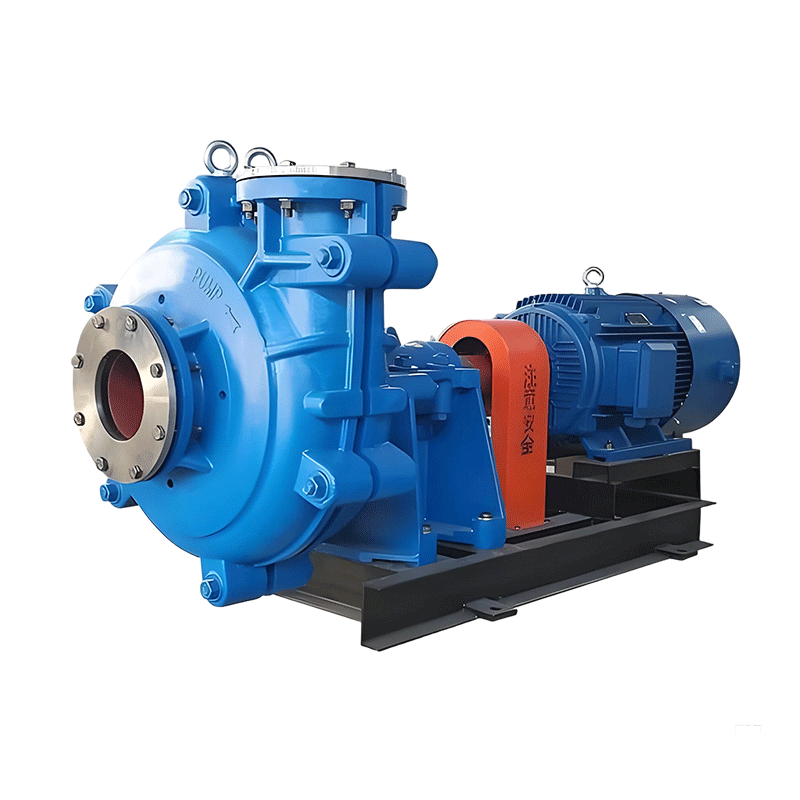

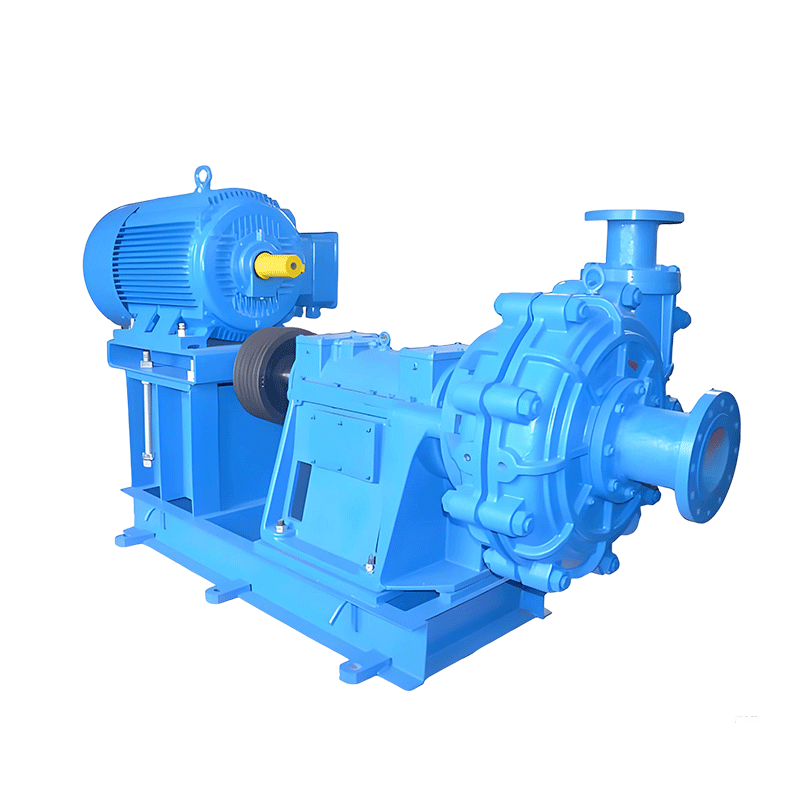

1. Easy installation and maintenance: the main shaft is horizontal, and the inlet and outlet flanges are basically on the same horizontal line. It is easy to install. During maintenance, the pump body, impeller and other components can be directly inspected and repaired without complicated disassembly.

2. Stable and reliable operation: the structural design is reasonable, the performance of components such as bearing components is reliable, and it can operate stably for a long time, has strong anti-blocking performance, and is not prone to blockage and jamming.

3. Wide range of applications: It can adapt to slurries of different properties by selecting flow components and sealing forms of different materials, with a wide range of flow and head, which can meet the needs of various working conditions.

The horizontal slurry pump works based on centrifugal force. After the motor is started, it drives the pump shaft and impeller to rotate, and centrifugal force is generated between the blades and the liquid. The liquid is thrown from the center of the impeller to the outer edge, and a low-pressure area is formed in the center of the impeller. Under the action of atmospheric pressure, the liquid flows in from the suction pipe, and the thrown liquid flows into the outlet pipe through the pump casing to realize the transportation of slurry containing solid particles.

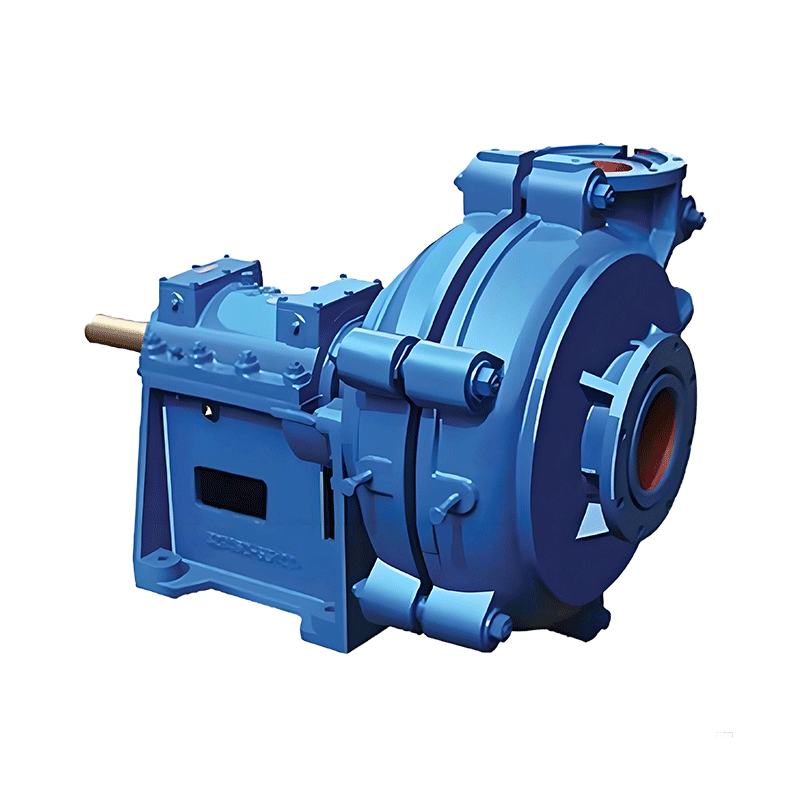

Structural composition:

1.Pump body: usually adopts a double-shell structure, and the inner shell can be a rubber lining or wear-resistant metal, such as high-chromium alloy, which can resist medium abrasion.

2.Impeller: a key component that transfers energy to the liquid. It is equipped with back blades to discharge the reflux slurry, increase the volume rate, and reduce reflux and erosion.

3.Pump cover: cooperates with the pump body to form a sealed space to ensure that the liquid flows according to the designed flow channel.

4.Bearing body: used to support the pump shaft, withstand the force and axial force under working conditions, and ensure that the impeller rotates on the same axis.

5.Bracket: Connects the pump body and the bearing body, plays a supporting and fixing role, and has various forms according to different working conditions and power requirements.

Performance parameters:

1.Flow rate: The flow rate range of different models of horizontal slurry pumps varies greatly, such as the flow rate of Metso MD series is 12000m³/h-52800USGPM, and the flow rate of X series is 10000m³/h-44000USGPM.

2.Lift: The lift of Metso Orion series H series can reach 100m-330ft, and the lift of M series can reach 60m-200ft.

3.Speed: Generally ranging from hundreds to thousands of revolutions per minute, the speed affects the performance of the pump such as flow rate, lift and efficiency.

4.Efficiency: The efficiency of efficient horizontal slurry pumps can reach more than 80%, and the new energy-saving slurry pumps are more efficient.

Application areas:

1.Mining industry: used for slurry transportation and tailings discharge in mineral processing plants, such as conveying the ground ore slurry to subsequent mineral processing processes.

2.Power industry: such as the hydraulic ash removal system of thermal power plants, which transports the mixture of fly ash and water to the ash treatment site.

3.Metallurgical industry: used in steel plants for slurry transportation in converter dust removal water, blast furnace gas washing water and other systems.

4.Dredging industry: used in dredging projects such as rivers and ports to pump mud, stones, etc. from the bottom of the water to designated locations

Company Strength:

Hebei Grandwatt Pump Industry Co., Ltd. has been deeply rooted in the water pump industry for many years, committed to delivering efficient and reliable pumping solutions to customers worldwide. With a modern manufacturing base covering over 30,000 square meters, our factory is equipped with intelligent production lines and advanced testing equipment. We boast an annual production capacity of more than 200,000 units, offering a comprehensive range of products including industrial pumps, submersible pumps, centrifugal pumps, and sewage pumps.

Our products are widely used in municipal engineering, agricultural irrigation, industrial circulation, and building water supply, among other sectors.