Mud Sucker Pump

1. It can deliver high-concentration, high-viscosity <10000PaS and suspended slurry containing particles. 2. The delivered liquid flow is stable, without over-flow, pulsation, stirring, and shearing of slurry. 3. The discharge pressure is independent of the speed, and a high discharge pressure can be maintained at a low flow rate. 4. The flow rate is proportional to the speed, and the flow rate can be adjusted by a speed-changing mechanism or a speed-regulating motor. 5. It has strong self-priming ability and can directly pump liquid without installing a bottom valve. 6. The pump can be reversed, and the direction of liquid flow is changed by the rotation direction of the pump, which is suitable for occasions where the pipeline needs to be flushed in the opposite direction. 7. It runs smoothly, with low vibration and noise. 8. It has a simple structure and is easy to disassemble and maintain.

Mud Pump is also a popular concept of a broad pump. Different regions and habits will eventually involve different pump types. The mud pump described in this entry is a type of pump in most senses: the mud pump used in the field of oil drilling. In fact, sewage pumps, slurry pumps and other non-clean water pumps and mud pumps are sometimes called the same. This entry explains to readers the mud pump in the field of drilling.

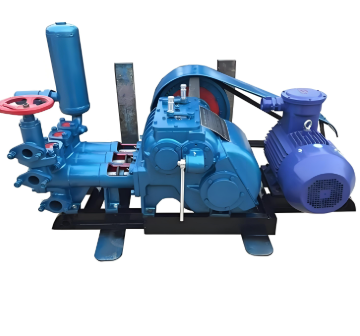

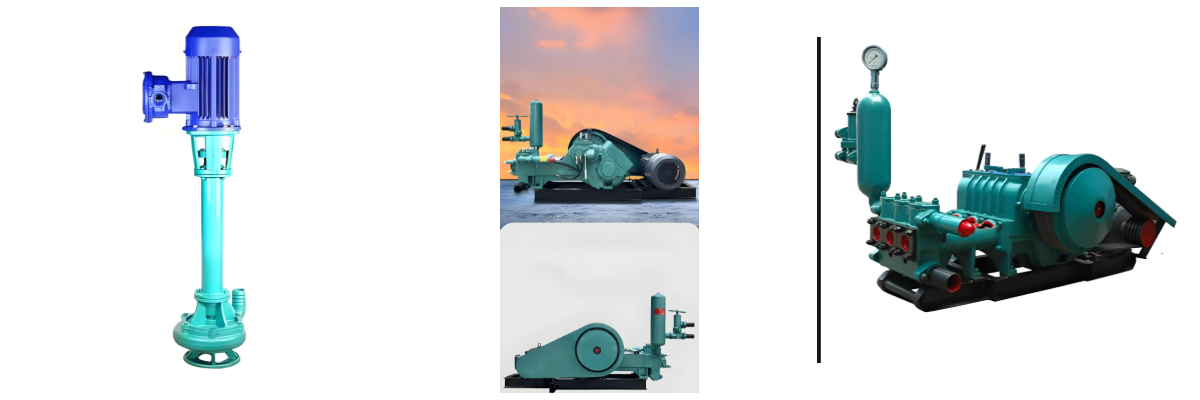

Mud pump refers to a machine that delivers mud or water and other flushing fluids into the borehole during the drilling process. Mud pump is an important part of drilling equipment.

In the commonly used positive circulation drilling, it is to send the surface flushing medium - clean water, mud or polymer flushing fluid under a certain pressure through a high-pressure hose, a faucet and the center hole of the drill string directly to the bottom of the drill bit to achieve the purpose of cooling the drill bit, removing the cut rock cuttings and transporting them to the surface.

Commonly used mud pumps are piston or plunger type. The power machine drives the crankshaft of the pump to rotate, and the crankshaft drives the piston or plunger to reciprocate in the pump cylinder through the crosshead. Under the alternating action of the suction and discharge valves, the purpose of pressurizing and circulating the flushing liquid is achieved.

The two main parameters of mud pump performance are displacement and pressure.

Displacement

The displacement is calculated as a number of liters per minute, which is related to the borehole diameter and the required return speed of the flushing fluid from the bottom of the hole, that is, the larger the borehole diameter, the larger the required displacement. The return speed of the flushing fluid is required to flush the rock cuttings and rock powder cut by the drill bit away from the bottom of the hole in time and reliably carry them to the surface. When drilling geological cores, the general return speed is about 0.4 to 1.0 meters per minute.

Pressure

The pressure of the pump depends on the depth of the borehole, the resistance of the channel through which the flushing fluid passes, and the properties of the flushing fluid being transported. The deeper the borehole, the greater the pipeline resistance and the higher the required pressure.

As the borehole diameter and depth change, the displacement of the pump is required to be adjusted at any time. A gearbox is provided in the pump mechanism or its speed is adjusted by a hydraulic motor to achieve the purpose of changing the displacement. In order to accurately grasp the changes in pump pressure and displacement, flow meters and pressure gauges should be installed on the mud pump to enable drillers to understand the operation of the pump at any time. At the same time, the pressure changes can be used to determine whether the conditions in the hole are normal to prevent accidents in the hole.