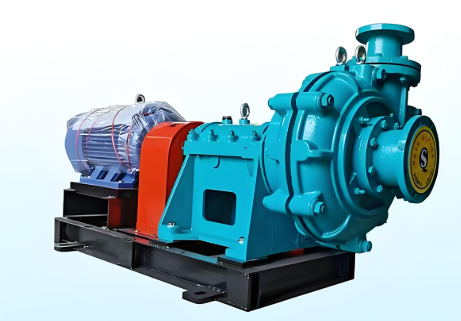

Horizontal slurry pump manufacturers

. Stable Structure, Reliable Operation

Rigid Support: The horizontal design allows the pump to be mounted on a stable foundation, resulting in minimal vibration and smoother operation.

Easy Maintenance: Bearings and seals are easily inspected and replaced, minimizing downtime.

Long Life: The heavy-duty design is suitable for continuous high-load operation, and wear-resistant parts (such as the impeller and guard) have a long replacement cycle.

A horizontal slurry pump is an industrial pump designed specifically for conveying high-concentration, highly abrasive, and highly corrosive slurries. It adopts a horizontal axial structure design and is widely used in mining, power, metallurgy, chemical industry, dredging and other industries. Its core features are strong wear resistance, stable operation, and convenient maintenance. It is suitable for long-distance and large-flow slurry transportation.

1. Basic structure and working principle

(1) Main components

Pump casing (volute): Made of wear-resistant materials (such as high chromium alloy, rubber lining), it withstands slurry erosion.

Impeller: Open/closed design, made of wear-resistant metal or rubber, it drives the slurry flow.

Shaft and bearing assembly: supports the pump rotor, and the external bearing design avoids slurry contamination.

Sealing system: commonly used auxiliary impeller + packing seal or mechanical seal to prevent leakage.

Base: firmly supports the pump body and reduces vibration. (2) Working Principle The motor drives the pump shaft to rotate through the coupling. The impeller rotates at high speed to generate centrifugal force. The slurry is sucked in from the inlet, accelerated by the impeller, and pressurized through the volute before being discharged from the outlet.