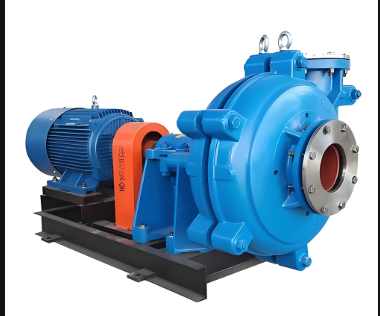

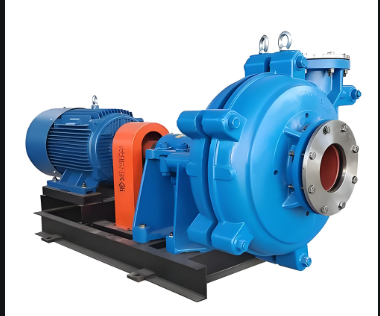

High-Efficiency Slurry Pump

It has a strong conveying capacity and can efficiently convey slurry materials containing a large amount of solid particles. It has a wide flow range and can be adjusted and selected according to different work needs to meet the conveying requirements under various working conditions.

In terms of operational performance, the horizontal slurry pump has a high head, which can lift the slurry to a higher position or transport it to a longer distance, ensuring smooth material transportation. In addition, it has good sealing performance and adopts a reliable sealing structure to effectively prevent slurry leakage, ensuring a clean working environment and the safety of operators.

Bearing Assembly: Cylindrical structure for easy maintenance, supports grease lubrication, and features an adjustable gap between the impeller and front guard.

Shaft Seal: Available with packing seal, impeller seal, or mechanical seal.

Drive: Supports various drive methods, including V-belts, elastic couplings, and gear reducers.

Applications: Primarily used for conveying liquids containing suspended solids (such as slurry, coal slag, and tailings), with solids concentrations up to 60% and temperatures not exceeding 80°C. Typical industries include metallurgy, mining, power generation, and building materials.

Maintenance Tips: Bearing cooling water temperature and packing seal leakage must be controlled to avoid cavitation caused by improper inlet valve adjustment. If abnormal vibration or noise is detected during operation, check the check valve for tightness and the packing gland for leakage.

Horizontal slurry pumps are widely used in industries such as mining, metallurgy, and power generation. They are primarily used to transport abrasive slurries containing solid particles. The horizontal slurry pumps available in our store weigh 11 kg, have a head of up to 25 meters, and a flow rate range of 26-34 lpm, adapting to a variety of working environments. Their compact design, measuring 300 mm in length and 200 mm in width and height, facilitates installation and maintenance. The pump body is constructed of wear-resistant materials, effectively resisting slurry abrasion and extending its service life. XGE8 O-rings seal the connections to ensure leak-free operation.