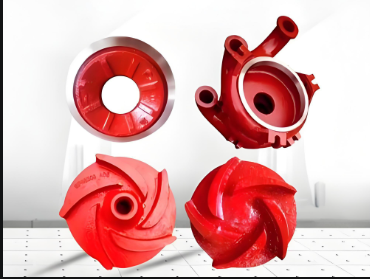

Slurry Pump Liner Plate

structural durability

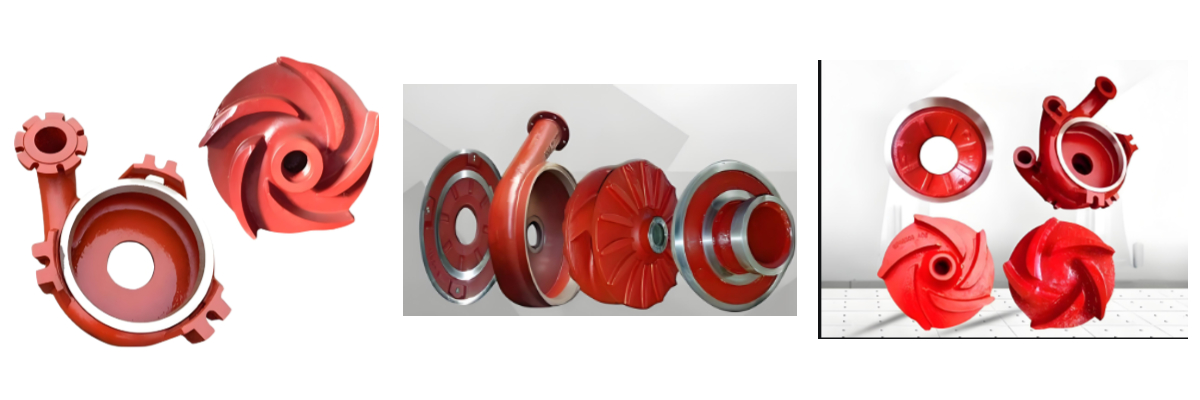

Most protecting plates undertake a double-layer steel structure, with a rotatable water outlet for effortless maintenance; Some fashions are geared up with disassembly rings to keep away from gear injury triggered by means of lack of ability to disassemble.

Applicable working conditions

High chromium alloy fabric has sturdy corrosion resistance, specifically appropriate for acidic and alkaline environments; Rubber lining cloth is appropriate for especially corrosive slurries, extending the equipment's working cycle

The slurry pump protect plate is one of the core glide elements of the slurry pump, normally used to shape a semi closed glide channel, permitting the slurry to run in it whilst defending the impeller and pump casing from put on and tear.

Material and Wear Resistance

Common substances for defensive plates consist of excessive chromium alloys (with exceptional put on resistance, appropriate for transporting slurry containing particles), A49 (with excellent corrosion resistance, in general used in desulfurization projects), etc. Rubber cloth protecting plate has desirable elasticity however is without difficulty punctured via sharp particles, whilst ceramic cloth has excessive hardness however excessive brittleness. In sensible applications, it wishes to be chosen in accordance to the working conditions.

central role

Protect the pump body: block the direct affect of stable particles in the slurry on elements such as impellers and pump casings, and prolong the carrier lifestyles of the pump.

Guide float channel: Cooperate with the sheath to shape a closed space, making sure that the slurry flows alongside the designed route and enhancing pump efficiency.

Reduce put on and tear: By designing moderately (such as labyrinth hole seals), limit the leakage of slurry to the packing and decrease factor wear.

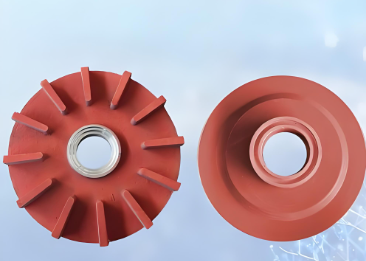

Installation and maintenance

During installation, it is indispensable to make sure even clearance with the impeller (usually 0.75~1.00mm) to keep away from put on or leakage brought about with the aid of being too tight or too loose.

Regularly check out fasteners to forestall looseness from inflicting vibration or leakage.

Keep the protecting plate smooth to forestall overseas objects from coming into and affecting the sealing overall performance