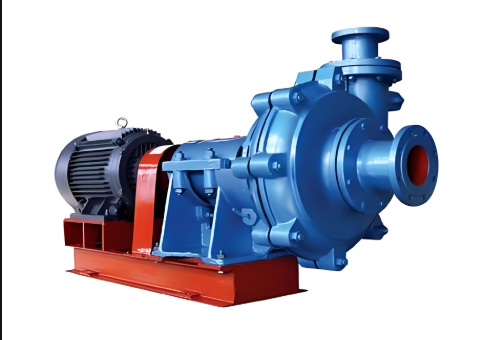

Slurry Transfer Pumps

This series of slurry pumps features innovative hydraulic and structural design. Flow components are constructed from a proprietary, wear-resistant, high-chromium alloy cast iron. They offer high efficiency, energy savings, long service life, lightweight, rational structure, reliable operation, low vibration and noise, and easy maintenance.

The pump body utilizes a double-casing design for easy replacement of flow components.

Depending on the pressure requirements, the outer casing is constructed from ductile iron or gray cast iron, while the inner casing is constructed from high-chromium, wear-resistant white cast iron or cast steel.

The ZJ slurry pump (also known as the EZJ type) is a single-stage, single-suction centrifugal industrial pump, mainly used in the power, metallurgy, coal and building materials industries to transport abrasive or corrosive slurries containing solid particles. The medium concentration can reach 45% for ash slurry and 60% for ore slurry, and the temperature does not exceed 60°C. It supports multi-stage series connection to meet long-distance transportation needs [1] [3] [8]. The pump adopts a horizontal double pump casing structure. The pump body and pump cover are equipped with replaceable high-chromium wear-resistant alloy linings (such as Cr27 material). The outlet direction can be rotated and adjusted at 45° intervals [1] [4-5]. The shaft seal provides three types of packing seals, auxiliary impeller seals and mechanical seals. The transmission methods include belts, couplings and gear reducers [7]. The flow-through parts are made of anti-wear materials and high-efficiency hydraulic design. It has a bimetallic pump casing, a vertical split structure and a cantilever centrifugal impeller, which can adapt to the impeller diameter and sealing scheme of different working conditions [2] [9]. Its typical application scenarios include ash removal in thermal power plants, mineral processing and transportation in mines, and coal slurry treatment.

This product offers high efficiency, energy saving, long service life, lightweight, rational structure, reliable operation, and easy maintenance. It is suitable for use in the power, metallurgy, coal, and building materials industries. It handles abrasive or corrosive slurries containing solid particles, with a solid-liquid mixture concentration of 45% for ash slurries and 60% for mineral slurries. The medium temperature is ≤ 60°C. This pump can be used in multiple stages

Pump Body, Pump Cover, and Wet Components: This series of pumps features a horizontal, vertical, double-casing slurry pump structure. The pump body and pump cover are equipped with a replaceable metal liner made of a high-chromium, wear-resistant alloy. The liner can be used until worn out, extending maintenance intervals and reducing operating costs. The pump outlet can be rotated in eight different directions.

Bearing Assembly: The pump's cylindrical bearing assembly facilitates adjustment of the clearance between the impeller and the front guard and can be removed as a whole for maintenance. The bearings are grease lubricated.

Shaft Seal: The pump's shaft seal types include stuffing box, impeller seal, and mechanical seal. Drive modes include V-belt drive, elastic coupling drive, gear reducer drive, hydraulic coupling drive, variable frequency drive, and thyristor speed control. V-belt drive types include CL, CV, CR, ZL, ZV, and ZR.

Overall Performance: The pump offers a wide performance range, excellent cavitation resistance, and high efficiency. Multi-stage cascade technology can be used to accommodate long-distance conveying. Wetted parts are available in a variety of metals and can be increased in depth. A variety of speeds and variations ensure optimal pump operation under industrial and mining conditions. The pump offers a long service life and high operational efficiency, meeting diverse and challenging conveying conditions.