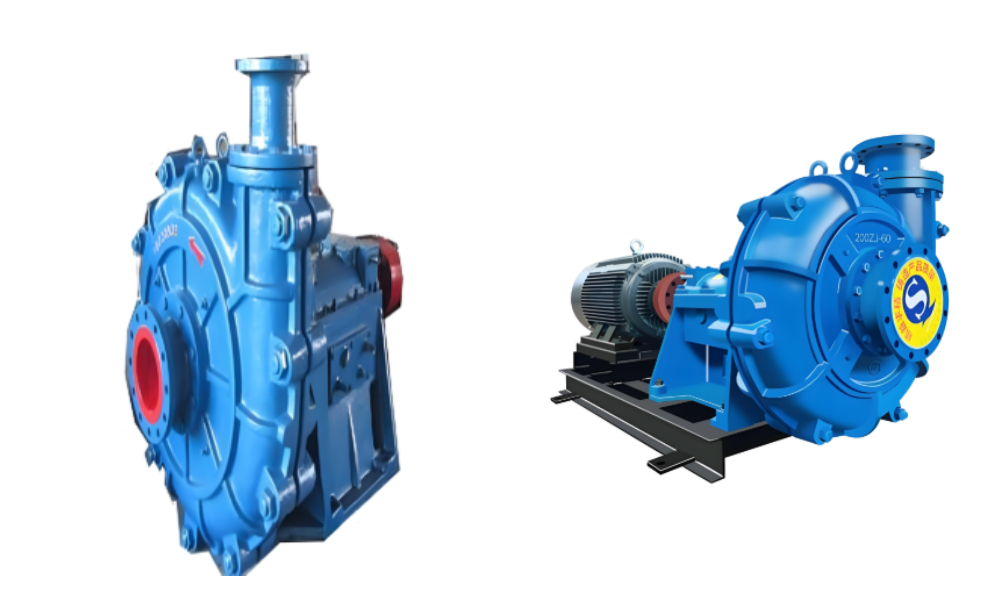

Heavy Duty Slurry Pump

(1) Unique wear-resistant design (structure and material) to ensure long service life of liquid-contacting parts.

(2) High efficiency of various performance and sludge pumps.

(3) Multi-stage series technology to meet long-distance transportation.

(4) High performance cost and simple maintenance.

(5) Various textures of liquid-contacting parts to meet various working conditions.

Heavy Slurry Pump is a device used to transport corrosive or high-hardness solid particles. It can maintain a flow rate of 15,000 cubic meters. Its shaft seal adopts packing seal or auxiliary impeller seal. It has the characteristics of long service life, high efficiency, long-distance transportation, high performance, etc. It is widely used in mining, electricity, metallurgy, coal and other industries, as well as environmental protection. First, let's talk about the relationship between centrifugal pumps and slurry pumps, and then the principle of slurry pumps will naturally become clear. The concept of centrifugal is from the pump principle. There are many kinds of pumps, which can be divided into dozens of categories according to different angles. Centrifugal pumps are divided from the working principle of the pump, which is the process of pressurizing the conveying medium through the action of centrifugal force. In addition, there are common types including screw principle, plunger principle, etc., which can be divided into pumps different from centrifugal principles. After talking about the concept of centrifugal pumps, let's talk about slurry pumps. Slurry pumps are divided from another perspective, that is, from the conveying medium. As the name suggests, slurry pumps convey a mixture of solid particles containing slag and water. But in principle, slurry pumps are a type of centrifugal pumps. In this way, these two concepts are explained clearly.

The main working parts of a centrifugal pump are the impeller and the casing. The impeller device in the casing is located on the shaft and connected to the prime mover to form a whole. When the prime mover drives the impeller to rotate, the blades in the impeller force the fluid to rotate, that is, the blades do work on the fluid along its direction of movement, thereby forcing the pressure potential energy and kinetic energy of the fluid to increase. At the same time, under the action of inertial force, the fluid flows from the center to the edge of the impeller, and flows out of the impeller at a very high speed, enters the extrusion chamber, and is discharged through the diffuser. This process is called the water pressure process. At the same time, because the fluid in the center of the impeller flows to the edge, a low-pressure area is formed in the center of the impeller. When it has sufficient vacuum, under the action of the suction end pressure (generally atmospheric pressure), the fluid enters the impeller through the suction chamber. This process is called the water absorption process. Due to the continuous rotation of the impeller, the fluid is continuously discharged and inhaled, forming a continuous operation.

The working process of a centrifugal pump (including a slurry pump) is actually a process of energy transfer and conversion. It transfers the mechanical energy of the high-speed rotation of the motor through the blades of the pump and converts it into the pressure energy and kinetic energy of the pumped fluid.