vacuum slurry pump

First, in terms of flow rate, it can provide a larger flow rate. Compared with the single-suction centrifugal pump, the design of the double-suction impeller can greatly increase the flow rate, meet the needs of large-scale fluid transportation in some large-scale industrial production processes, such as large-scale water conservancy projects, chemical production and other fields, and provide a strong guarantee for the continuity of production.

Secondly, it performs well in head performance. The double-suction impeller is symmetrically arranged, so that the liquid is sucked on both sides of the impeller, which effectively balances the axial force and reduces the consumption of shaft power, so that a higher head can be obtained.

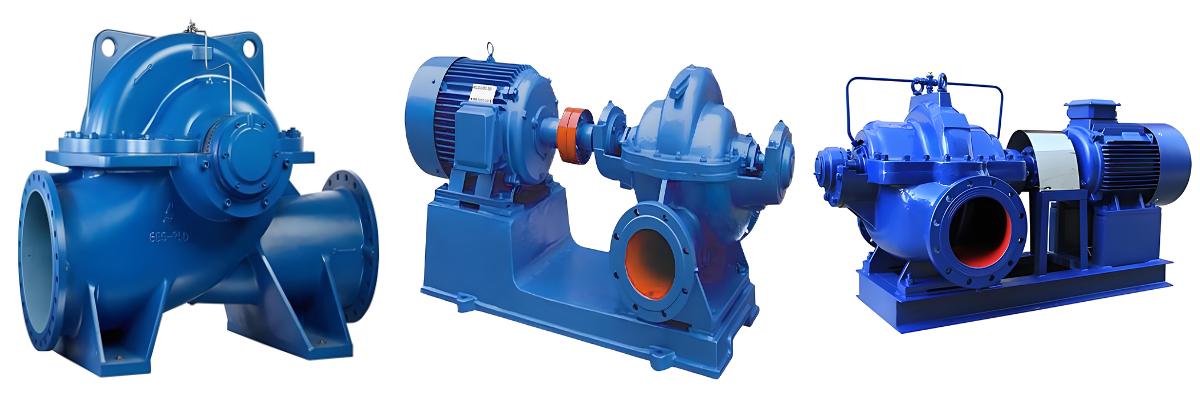

Double-suction centrifugal pumps are highly favored for their unique performance and wide range of applications. They are mainly used to transport clean water or other liquids with physical and chemical properties similar to water. According to user needs, by changing the pump structure and material, they can also be used to transport muddy water or various corrosive liquids. Double-suction centrifugal pumps play an important role in factories, mines, urban water supply and drainage, power stations, farmland irrigation and drainage, and various water conservancy projects. This wide range of applications makes double-suction centrifugal pumps an indispensable part of the water pump market.

High efficiency and energy saving: The double-suction centrifugal pump adopts an excellent hydraulic model and is optimized through CFD computational fluid dynamics analysis methods to significantly improve its efficiency. The maximum efficiency of some high-end models of double-suction centrifugal pumps can exceed 92%, achieving the goal of both high efficiency and energy saving.

Smooth operation: The optimized design of the double-suction centrifugal pump reduces its axial force to a minimum, and the inner surface of the impeller and pump casing is smooth, with significant anti-cavitation performance and high efficiency. This design not only ensures the smooth operation of the pump, but also extends the service life of the pump.

Low noise and long life: The optimized design of the bearing components makes the double-suction centrifugal pump low noise and long service life during operation. At the same time, the shaft seal uses a mechanical seal or a packing seal to ensure long-term operation without leakage.