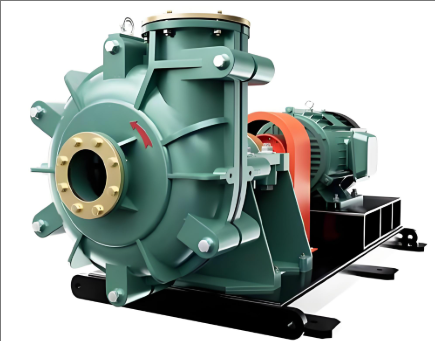

Heavy Duty Slurry Pum Por Sale

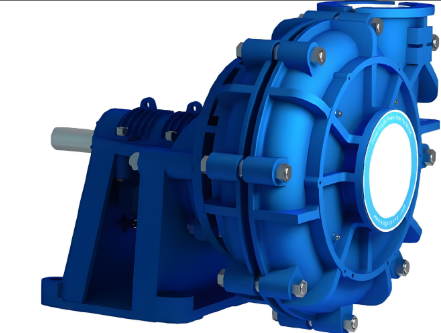

1) The rubber front plate can work for 205 days.

(2) The rubber impeller equipped with the sludge pump enjoys a long service life (about 120 days, as long as other impellers twice).

(3) High wear-resistant rubber

This rubber is characterized by high elasticity, chemical stability, anti-cavitation and small density. In addition, it absorbs noise and vibration, making heavy slurry pumps light and easy to install and replace fluid parts.

Slurry pumps can be widely used in mining, power, metallurgy, coal, environmental protection and other industries to transport slurries containing abrasive solid particles. Such as slurry transportation in metallurgical ore dressing plants, hydraulic ash removal in thermal power plants, coal slurry and heavy medium transportation in coal washing plants, dredging of rivers, river silt removal, etc. In the chemical industry, some corrosive slurries containing crystals can also be transported. First of all, in the application of ore dressing plants, about 80% are used in ore dressing plants in the mining industry. Due to the harsh working conditions of the primary selection of ore, the service life of slurry pumps is generally low in this section. Of course, different ores have different abrasiveness. For example, in the section of concentrate transportation, the relative abrasiveness is reduced, and the overall service life of the pump is longer. Therefore, when general users often ask about the service life of suppliers' products during the procurement process, strictly speaking, no manufacturer will promise users an accurate service life cycle without basis, because the service life of the flow-through parts (wear-resistant and corrosion-resistant parts) depends on many different factors, and the diversity and complexity of working conditions lead to differences in the service life of materials of the same quality. However, in the early stage of selection, powerful manufacturers can be asked to make reasonable working condition selection and design for it. Secondly, in the power industry, it is mainly thermal power plants. At present, my country's power plants are mainly thermal power generation and hydropower generation. In thermal power plants, due to the large amount of coal-fired power generation, the slag or ash after coal combustion needs to be removed. Slurry pumps are used to remove ash and slag. After mixing a certain amount of water, the slag is transported to the place where the ash is piled through a slurry pump. Therefore, sometimes slurry pumps are also called ash pumps in power plants. Thirdly, in the coal washing industry, due to different working conditions, larger coal blocks and coal gangue are prone to blockage, and the design requirements for slurry pumps are very high. In 2005, a coal washing plant under the Huaibei Mining Bureau adopted a specially designed slurry pump to replace the original slurry pump imported from Australia. It has been operating normally so far, transporting larger coal blocks and coal gangue without blockage, and its service life exceeds that of imported pumps from abroad. In the field of seawater sand selection, the application of slurry pumps has also begun to be gradually recognized by customers. However, when selecting sand in seawater and dredging sand in rivers, slurry pumps are more likely to be called sand pumps and dredging pumps. Although the names are different, they can all be called slurry pumps in terms of structural characteristics and pump performance principles. Therefore, we often call it a sand pump in seawater sand selection, and dredging pumps in river dredging. Although slurry pumps have a wide range of uses, correct application is very important. Due to the limitations of the name itself, slurry pumps have caused some people outside the industry to misunderstand it. In fact, mud pumps, impurity pumps, dredging pumps, dredging pumps, etc. are all within the application range of slurry pumps. In the application process of slurry pumps, we must pay attention to reasonable design, correct calculation, and appropriate selection. These points are very important.