Slurry Tanker Vacuum Pump Oil

1. High Flow and High Efficiency

High-Flow Delivery: The double-suction structure doubles the water inlet area, significantly increasing flow rates compared to single-suction pumps. It's suitable for high-flow applications such as water supply, irrigation, and industrial circulation.

Higher Efficiency: Water flows evenly from both sides of the impeller, reducing vortex and impact losses. Hydraulic efficiency is typically 3%-5% higher than single-suction pumps, resulting in significant energy savings over long-term operation.

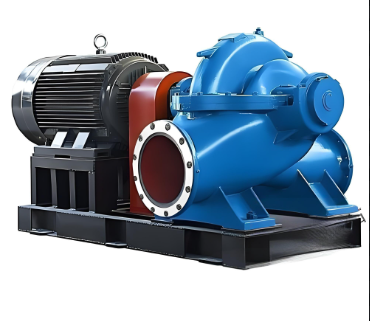

A double-suction pump is a specially designed centrifugal pump featuring a double-sided impeller inlet structure. Water enters from both sides of the impeller and is discharged through centrifugal force. This design offers advantages such as maximum flow, high efficiency, and low cavitation, making it widely used in municipal water supply, industrial circulation, agricultural irrigation, and other fields.

1. Structural Features of a Double-Suction Pump

The core features of a double-suction pump are perfectly symmetrical dual suction inlets and a horizontally split case design. Its main features include:

Double-suction impeller: Water inlet from both sides, high flow rate, and automatic axial force balancing.

Horizontally split case: The pump body is split horizontally along the axis for easy maintenance and inspection.

Dual bearing support: More stable operation and longer bearing life.

Double seal structure: Suitable for high-pressure and high-flow conditions.

Compared to single-suction pumps: Single-suction pumps only have water inlet from one side, resulting in lower flow rate and axial thrust, requiring additional balancing devices.

2. Working Principle of a Double-Suction Pump

1. Inlet Phase: Liquid enters the impeller simultaneously from both sides of the pump body. 2. Centrifugal Supercharging: The impeller rotates at high speed, and the liquid is driven by centrifugal force to flow toward the outer edge of the impeller, converting kinetic energy into pressure energy.

3. Discharge Phase: The high-pressure liquid is collected in the volute and discharged from the outlet.

Due to the symmetrical double-suction design, axial forces offset each other, resulting in smoother pump operation and reduced bearing loads.