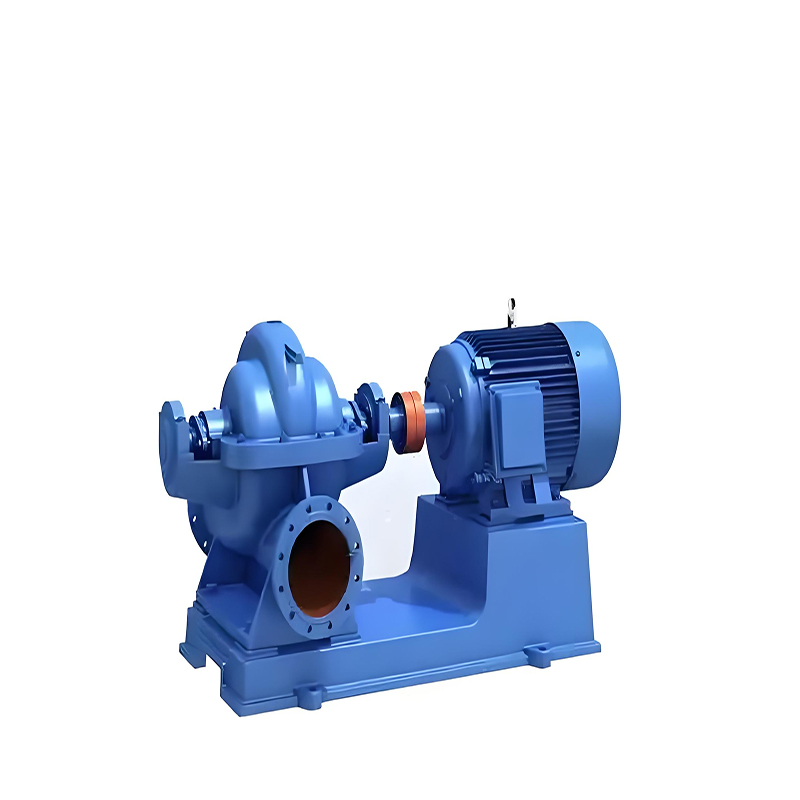

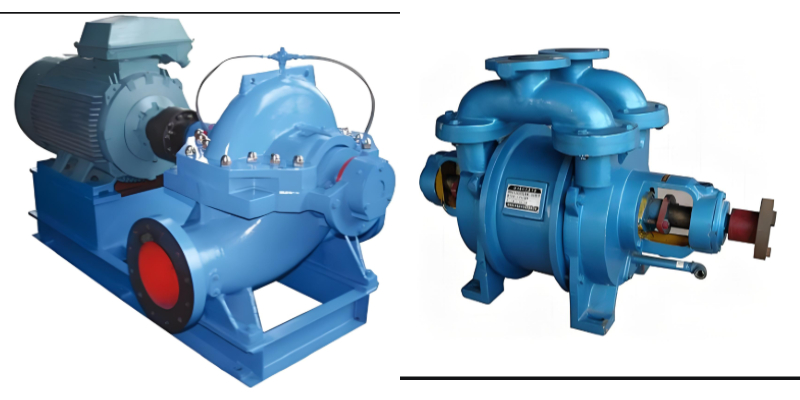

Double Suction Split Pump

Smooth operation and balanced axial force:

Due to the symmetrical water inflow on both sides of the impeller, the axial forces generated are basically offset. This greatly reduces the load on the bearing and significantly increases the life of the bearing and the entire pump.

The vibration and noise during operation are usually low, and the operation is very smooth and reliable.

3. Balanced radial force:

The double-suction structure also makes the radial force acting on the impeller well balanced, reducing the risk of shaft bending and deformation, and further improving the stability of operation.

Double suction split pump (also known as horizontal split double suction centrifugal pump) is a large flow centrifugal pump with special structure and superior performance. It is widely used in industry, municipal administration, water conservancy and other fields. The following is a systematic introduction to its core elements:

I. Name analysis

Double suction: liquid is sucked from both sides of the impeller at the same time (axial water inlet), and the flow area is doubled.

Split type: The pump casing adopts** horizontal split design, and is horizontally divided into upper pump cover and lower pump body along the axis.

Core structure: double suction impeller + horizontal split pump casing.

II. Core structure features**

1. Pump casing (horizontal split)

Divided into upper cover (pump cover) and base (pump body), fastened by bolts.

No need to dismantle pipelines for maintenance**: just open the upper cover to expose all internal parts (impeller, shaft, seal, etc.).

2. Double suction impeller

- The impeller is designed symmetrically on both sides, and the liquid enters from both ends at the same time.

- The axial force is automatically balanced to reduce the bearing load.

3. Support structure

The bearing box is independent of the pump body and usually adopts rolling/sliding bearings to support high load and long cycle operation.

The shaft seal form is flexible (mechanical seal, packing seal, etc.).

4. Easy maintenance (the core advantage of the split/horizontal split design):

No need to disassemble the inlet and outlet pipes and motor! The pump casing is horizontally divided into an upper pump cover (pump cover) and a lower pump body (pump body) along the axis.

During maintenance, you only need to loosen the pump cover bolts and lift the pump cover to fully expose the inside of the pump chamber (including all rotating parts such as impellers, shaft seals, sealing rings, bearings, etc.).

This makes it extremely convenient and quick to inspect, maintain, and replace parts (such as impellers, mechanical seals, and mouth rings), greatly shortening downtime and reducing maintenance costs and workload.

5. High efficiency:

The double suction design reduces the flow velocity at the impeller inlet, thereby reducing hydraulic losses, and usually achieves higher efficiency than single suction pumps, especially under high flow conditions.

High efficiency means lower operating energy consumption.

6. Good cavitation performance:

Also thanks to the double suction design that reduces the inlet flow velocity, the pump's required cavitation margin is usually lower, and it has **better anti-cavitation performance**. This makes it more adaptable to conditions with low inlet pressure or liquid close to saturated vapor pressure.

7. Structural features:

Relatively large volume and heavy weight: Due to the double suction impeller and split structure, its volume and weight are usually larger than single suction pumps with the same flow rate.

High manufacturing cost: The structure is relatively complex, and the processing accuracy requirements are high (especially the sealing of the middle split surface), and the manufacturing cost is usually higher than that of single suction pumps.

Inlet and outlet direction: The inlet and outlet flanges are usually located on both sides of the lower half of the pump body (pump body), in a horizontal direction (perpendicular to the axis), which is convenient for pipeline layout