slurry tanker pump for sale

Structural features:

Relatively large volume and heavy weight: Due to the double-suction impeller and split structure, its volume and weight are usually larger than those of a single-suction pump with the same flow rate.

High manufacturing cost: The structure is relatively complex, and the processing accuracy requirements are high (especially the sealing of the center split surface), and the manufacturing cost is usually higher than that of a single-suction pump.

Inlet and outlet direction: The inlet and outlet flanges are usually located on both sides of the lower half of the pump body (pump body), in a horizontal direction (perpendicular to the axis), which is convenient for pipeline layout.

In summary, the core features and advantages of the double-suction split pump are:

Ultra-large flow delivery capacity.

Excellent running stability and long life (thanks to the axial/radial force balance).

Extremely convenient maintenance (horizontal center split design).

High operating efficiency.

Good anti-cavitation performance.

Main applicable scenarios:

Occasions where large flow rates of liquid need to be transported.

Occasions where stable and reliable operation and long-term continuous operation are required.

Occasions where maintenance convenience is required.

Occasions where efficiency requirements are high**.

Occasions where the inlet pressure may be low or the liquid is easy to vaporize.

Typical applications:

Urban water supply and drainage (water supply, water delivery, and pressure station of waterworks).

Hot and cold water circulation of large building air conditioning systems.

Industrial cooling water systems.

Power station circulating water and condensate water.

Large farmland irrigation.

Process water for large factories.

Fire protection system water supply.

Seawater desalination plants, etc.

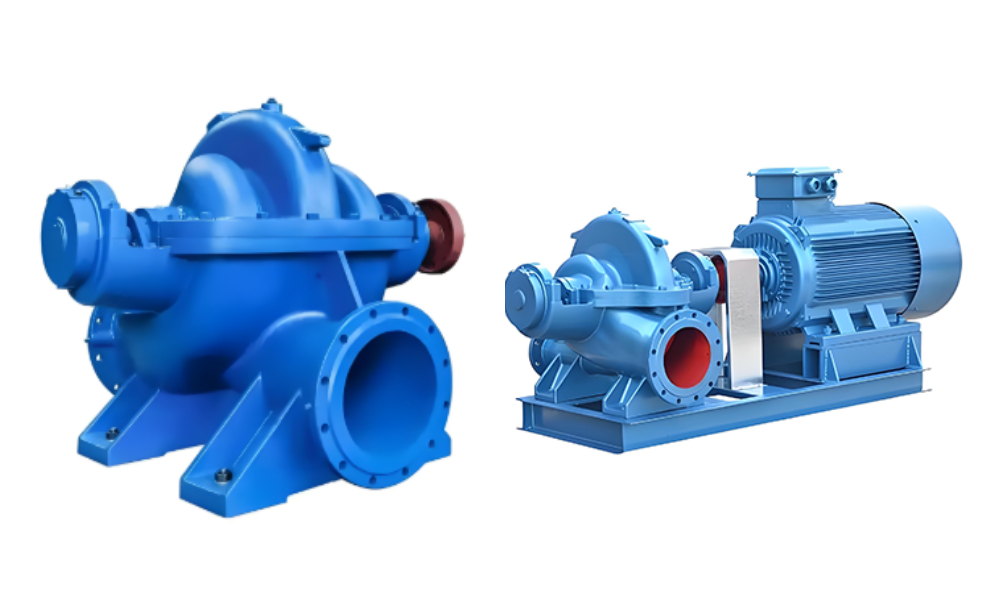

The double-suction centrifugal pump realizes fluid transportation primarily based on centrifugal force, and its core is the double-suction impeller. When the motor drives the impeller to rotate at excessive speed, a low-pressure place is fashioned in the middle of the impeller. The liquid enters from each aspects of the impeller (double suction port) at the identical time, and is thrown to the volute by using the impeller after merging, and then discharged via the outlet. This graph is equal to two single-suction impellers of the identical diameter working at the equal time, and the go with the flow fee can be doubled underneath the identical impeller outer diameter. At the identical time, due to the symmetrical shape of the impeller, the axial forces offset every other, lowering the burden on the bearings and making the pump run extra smoothly.

Strctural features

Horizontal cut up pump body: The pump physique is divided into higher and decrease halves horizontally alongside the axis, which is handy for rapid disassembly and meeting at some stage in preservation barring disassembly of the pipeline.

Double-suction impeller design: appreciably minimize axial force, the impeller and pump casing have awesome hydraulic models, are precision cast, have easy internal surfaces, and have notable anti-cavitation performance.

Double volute structure: successfully minimize radial force, limit bearing stress, and prolong bearing provider life.

Shaft seal selection: mechanical seal or packing seal can be selected, and some fashions can make sure long-term leakage-free.

Various set up forms: no adjustment is required for the duration of assembly, and it can be mounted one by one or horizontally in accordance to the on-site use conditions.

Self-priming gadget can be installed: computerized water absorption is achieved, no backside valve or vacuum pump desires to be installed, and it can be started out barring backflow.

Application field

Water therapy industry: normally used in water supply, water supply, circulating water gadget and sewage treatment, etc., and can transport easy water, sewage, seawater, bloodless water, etc.

Petrochemical industry: extensively used in petroleum, chemical, herbal fuel and different industries, such as crude oil transportation or therapy of more than a few chemical elements in refineries.

Heating and air conditioning: used to transport warm water and cooling water to keep the temperature of buildings.

Power industry: transport cooling water to the cooling tower or cooling gear of the strength plant, and is additionally regularly used to pump water to the boiler of the thermal energy plant.

Forestry and agriculture: used for irrigation, hydrological structures and water useful resource administration in forestry, and frequently used to transport irrigation water in the agricultural field.

Papermaking and meals industry: used to transport drinks such as pulp and meals slurry