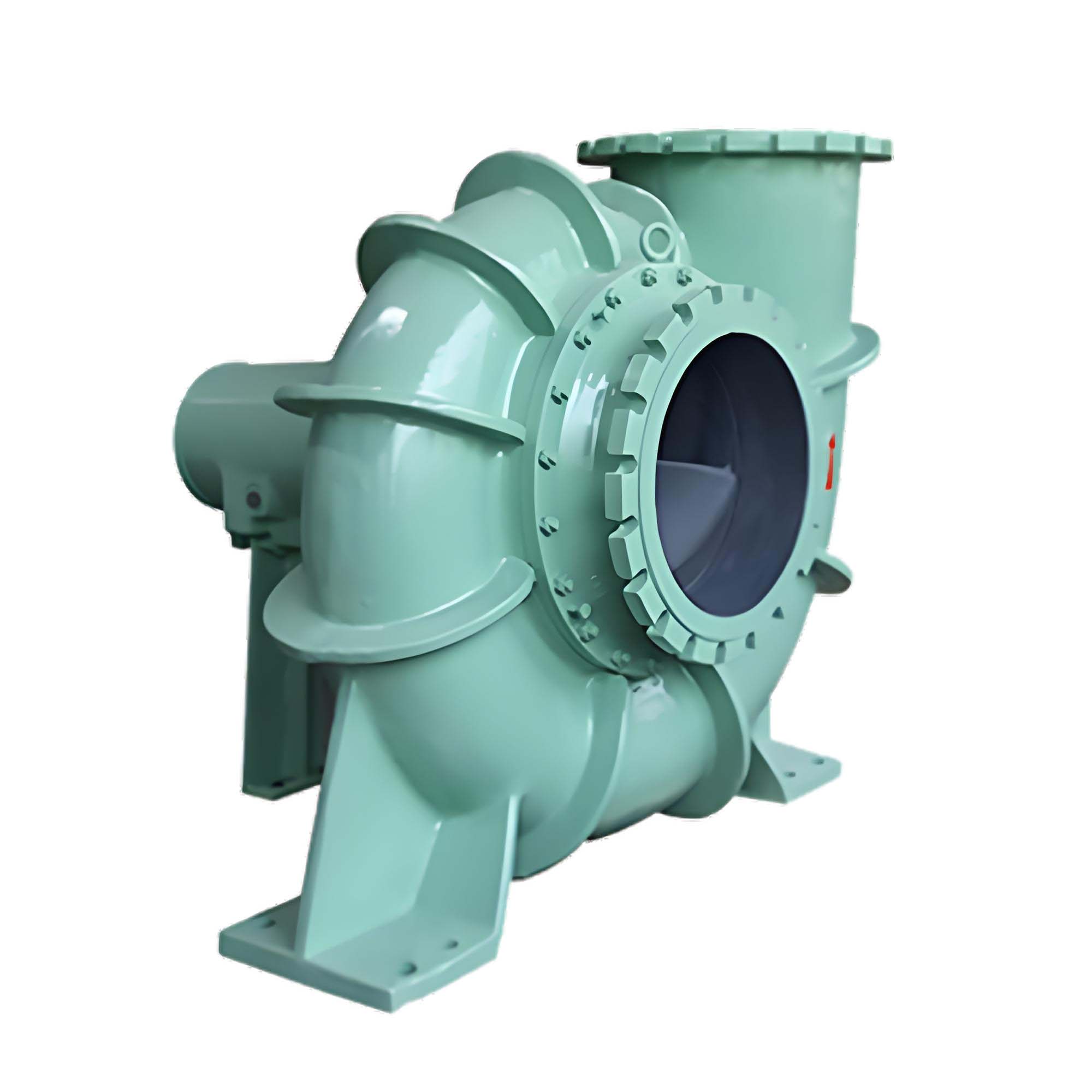

Pompa Double Impeller

(1) Strong wear resistance: All flow-through parts are made of steel-lined ultra-high molecular weight polyethylene (UHMW-PE). The wear resistance of ultra-high molecular weight polyethylene (UHMW-PE) ranks first among plastics, 4 times higher than nylon 66 (PA66) and polytetrafluoroethylene (PTFE), and 7-10 times the wear resistance of carbon steel and stainless steel.

(2) Strong impact resistance: The impact strength of ultra-high molecular weight polyethylene ranks first among general engineering plastics, 5 times that of (acrylonitrile/butadiene/styrene) copolymer (ABS), and can remain stable at minus 196°C, which is a feature that no other plastic has.

(3) Excellent corrosion resistance: The pump can withstand various corrosive media (acids, alkalis, salts) and organic solvents within a certain temperature and concentration range. It can be immersed in 80 organic solvents at 20°C and 90°C for 30 days. There is no abnormality on the surface, and other physical properties are almost unchanged.

Except for the different structures of the head part (including the front and rear pump casings, volutes, front and rear guard plates, impellers, etc.), the rest of the structures are similar and use the same series of transmission parts. The following describes the structural characteristics of the pump head part, shaft seal part and transmission part respectively.

Pump head part

GMZ series pumps are double pump casing structures, namely the front pump casing, the rear pump casing and the replaceable flow-through parts (including the impeller, volute, front guard plate and rear guard plate). The front and rear pump casings are made of gray cast iron or ductile iron according to the working pressure, vertically opened in the middle, and connected with bolts. The rear pump casing has a stopper and is connected with the bracket by bolts. The discharge port of the pump can be rotated and installed at eight angles. The front and rear cover plates of the impeller have back blades to reduce leakage and improve the life and efficiency of the pump. The inlet of each type of pump is horizontal, and the pump rotates clockwise from the transmission direction.

Shaft seal part

There are three types of shaft seals, auxiliary impeller shaft seal, packing shaft seal, and mechanical seal.

(1) Impeller seal: When the positive pressure value of the pump inlet is not more than 10% of the pump outlet pressure value, the impeller seal can be used for the single-stage pump or the third-stage pump in multi-stage series. The impeller seal has the advantages of not diluting the slurry and good sealing effect.

(2) Packing seal: The packing seal has a simple structure and is easy to maintain. It needs to use seal water. For working conditions that are not suitable for impeller seals and pump suction, packing seals can be used.

(3) Mechanical seal: For working conditions that are not suitable for the above two types of seals, mechanical seals are used to reduce the maintenance times of the seal part.

Transmission part

This series of pumps all use the same series of transmission, including brackets and bearing assemblies. The pump shaft has a large diameter, good rigidity, and short cantilever. It will not bend or vibrate under harsh working conditions. The bearings are a combination of single-row tapered roller bearings and angular contact ball bearings, which can withstand the maximum axial and radial loads of the pump. The bearings are lubricated with lithium-based grease. The advantages of this lubrication are: high oil film strength; good grease adhesion, not easy to lose, and long service life; simple sealing, with sealed end covers at both ends of the bearing body, which can effectively prevent dirt such as slurry from entering the bearings.