Pump Throat Bushing

Improve operational stability: It helps stabilize the flow of slurry, reduce turbulence and eddy currents in the slurry, reduce vibration and noise during pump operation, enable the slurry pump to operate more smoothly, and improve the operational stability and reliability of the equipment.

- Reduce wear: Direct contact with the transported slurry can protect the key components of the pump body, such as the impeller and volute, from erosion and wear by solid particles in the slurry.

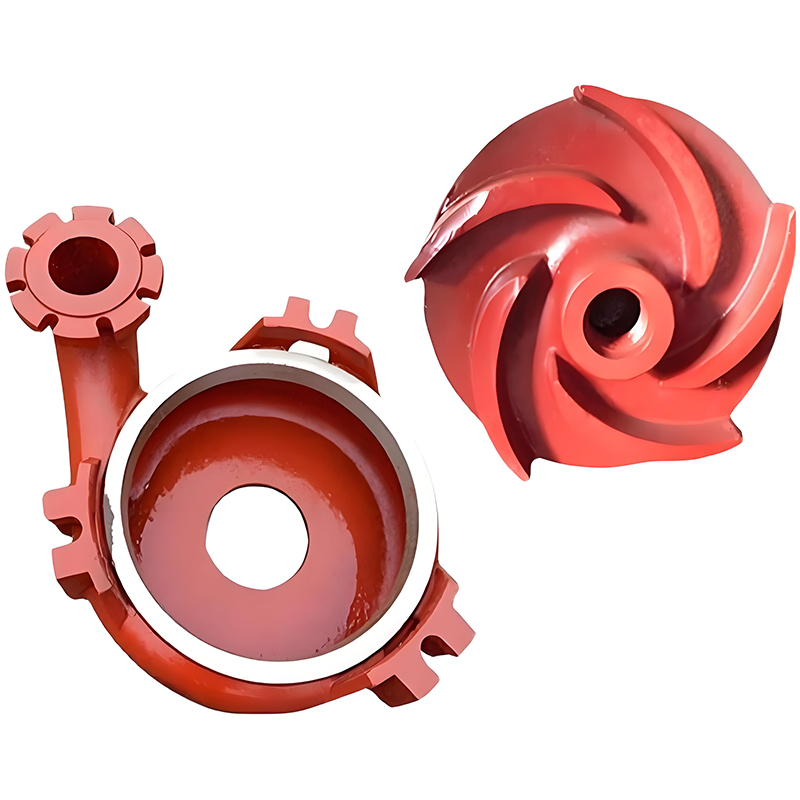

The slurry pump guard plate is a key flow-through component of the pump. It is in direct contact with the slurry. Its main function is to cooperate with the sleeve to form a semi-closed flow channel to guide the slurry to flow along a specific path. The following are the details:

Material

The guard plate is usually made of wear-resistant alloy, rubber or polyurethane. Wear-resistant alloy has high hardness and good wear resistance but poor corrosion resistance; rubber has better conveying effect on slurry with smaller particles, and has both wear resistance and corrosion resistance; polyurethane has good wear resistance and adapts to fatigue wear.

Structure and function

The guard plate and the sleeve form a flow channel, and the flow rate and head are controlled by adjusting the gap between the two. Too large a gap may lead to increased volume loss, decreased efficiency and seal failure.

Wear type

General wear: caused by slurry scouring, the surface shows corrugated erosion marks, which are common on the outer edge of the guard plate and the impeller blade area.

Local wear: deep grooves, holes and even perforations caused by deterioration of flow state, mostly occur at the junction of the guard plate and the impeller.

Replacement and Maintenance

The guard plate is a consumable part and the gap size needs to be checked regularly (it is recommended to keep it within a reasonable range). When it is severely worn, it needs to be replaced to ensure pump efficiency and sealing performance.