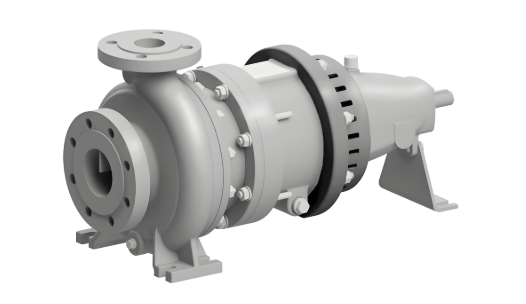

Horizontal Single-Case Pump

Structure and Maintenance

The single-stage, single-suction design simplifies maintenance by eliminating the need to disassemble the inlet and outlet piping.

Compared to a double-suction design, it offers a lower center of gravity and more stable operation.

Applicable Applications

This device is suitable for intermittent use in applications such as household drainage and agricultural irrigation, offering a low cost.

However, attention should be paid to the cleanliness of the media to prevent particulate matter from abrading the flow path components.

A single-casing slurry pump is a gadget with a single casing (i.e., the pump physique and pump cowl are critical or combined). The pumped medium (slurry containing stable particles) immediately contacts the internal wall of the casing, and the centrifugal pressure generated via the rotation of the impeller is used to transport the medium. The casing is usually forged or welded in one piece, ensuing in a exceptionally easy structure.

2. Classification

By casing material:

Metal single-casing pumps: Casings made of steel substances such as high-chromium forged iron and wear-resistant metal are appropriate for surprisingly abrasive media with giant particle sizes (such as ore slurries and gravel slurries).

Rubber single-casing pumps: Casings lined with rubber or built completely of rubber provide great corrosion and put on resistance, making them appropriate for conveying medium-sized particles and corrosive media (such as chemical slurries and mud).

By structural type:

Horizontal single-casing pumps: The pump shaft is organized horizontally. They are the most extensively used and appropriate for traditional working conditions.

Vertical single-casing pumps: The pump shaft is organized vertically. They can function immersed in the medium (such as submersible pumps) and are appropriate for purposes requiring submerged installation.