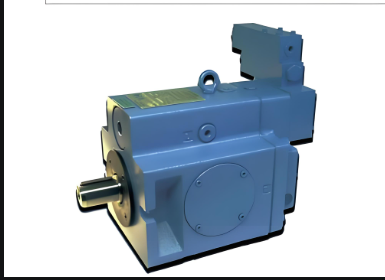

High Pressure FGD Pump

High Pressure and Flow Control

Flow rate can be flexibly adjusted by varying the plunger stroke to meet varying operating conditions.

High pressure characteristics (up to 10 MPa and above) meet the pressure stability requirements of desulfurization systems. However, mechanical clearance under high pressure may cause flow fluctuations (±5%), necessitating use with a pressure stabilizer.

Efficiency and Lifespan

Volume efficiency is approximately 95%, and overall efficiency reaches 90%, resulting in a long lifespan.

However, the complex structure requires high manufacturing precision and regular maintenance. It is sensitive to oil contamination and requires a precision filtration system.

Flue fuel desulfurization (FGD) plunger pumps are key gear used in moist FGD systems. They are specially used to transport slurries containing strong particles (such as limestone slurries and gypsum slurries). They characteristic put on resistance, corrosion resistance, and dependable operation.

Operating Principle

A plunger pump makes use of the reciprocating movement of the plunger rod to exchange the chamber volume, producing a stress differential to transport liquid.

When the plunger strikes inward, the chamber extent decreases, pushing liquid out; when it strikes outward, liquid is drawn in. This reciprocating movement allows the pump to function continuously, making it appropriate for transporting high-pressure, high-viscosity media.

Key Features

Wear-Resistant Materials: Flow-through factors are built of all-metal, wear-resistant substances (such as chromium-nickel alloys) to face up to the abrasive prerequisites of stable particles in slurries, attaining dynamic put on resistance of 0.008-0.08 mm/year.

Optimized Structure: Components such as the impeller and volute make use of a solid-liquid two-phase drift hydraulic model, supplying more advantageous cavitation resistance and 3%-5% greater effectivity than non-metallic pumps.

Seal Design: A cartridge-type mechanical seal and back-vane shape successfully stop strong particles from coming into the seal chamber, extending provider life.