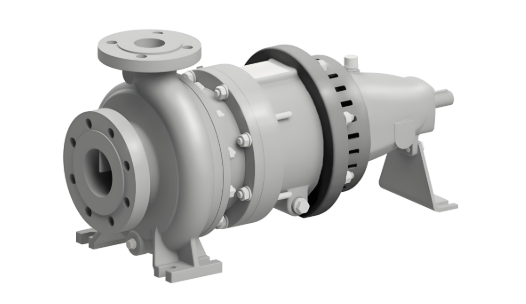

Chemical Single Case Pump

1. Simple Structure, Easy Maintenance

Single-shell design: Compact structure, easy assembly and disassembly, and maintenance, reducing downtime.

Axial suction, radial discharge: Optimized flow path reduces hydraulic loss and improves efficiency.

Rear-opening door: Maintenance requires no removal of inlet and outlet piping, reducing maintenance costs.

1. Definition and Basic Structure

A horizontal single-volute pump is a single-stage, single-suction centrifugal pump with a horizontal axial suction and radial discharge design. The pump body features a single-piece volute structure. Its main components include:

Pump casing (single volute): Monolithic casting, simple structure, and high strength.

Impeller: Typically a closed or semi-open design, suitable for clean liquids or those containing light particles.

-Shaft and bearings: Heavy-duty bearings are used to support stable operation.

-Sealing method: Mechanical seals or packing seals are available to meet the needs of different media.

2. Operating Principle

Horizontal single-volute pumps operate based on the principle of centrifugal force:

1. Axial liquid inlet: The medium enters the pump chamber through the horizontal inlet.

2. Impeller rotational acceleration: The high-speed rotation of the impeller transfers kinetic energy to the liquid, generating centrifugal force.

3. Volute collection and pressurization: The liquid is collected and decelerated in the volute, where kinetic energy is converted into pressure energy before being discharged through the radial outlet.