Single-Casing Vertical Pump

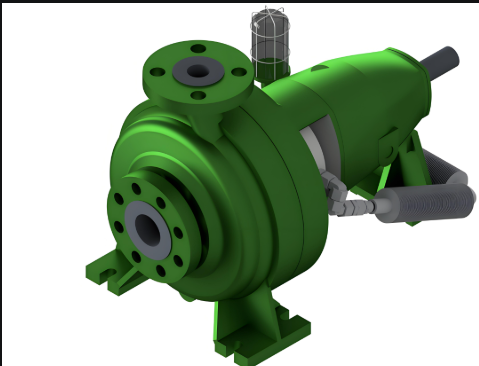

Compact and space-saving structure

Vertical pumps utilize a vertical design, resulting in a compact size, lightweight weight, and minimal installation footprint. Some models can be installed outdoors with a protective cover, eliminating the need for a machine room and saving on infrastructure costs.

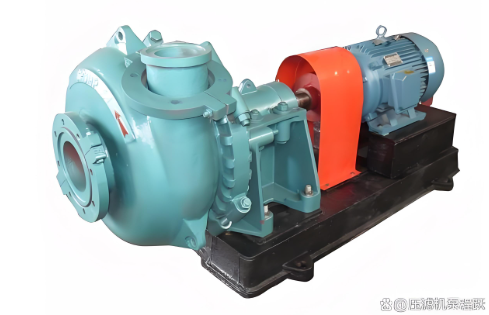

A vertical single-casing pump is a vertical pump with a single-layer pump casing. It is primarily used to handle abrasive or corrosive slurries containing solid particles. Its structural features and functions are as follows:

Structural Features

Pump Design: Utilizes a single-layer metal pump casing with a vertical split-case structure. The pump casing and pump cover are integrated, directly bearing the pressure.

Sealing Method: Typically equipped with a mechanical seal, a stuffing box seal, or a expeller dynamic seal to ensure sealing under high-pressure conditions.

Drive Method: Supports direct drive, hydraulic coupling, or belt drive, adapting to different power systems.

Application Scenarios

Industrial Applications: Suitable for use in the power, metallurgy, coal, and building materials industries. It handles abrasive or corrosive slurries with temperatures ≤60°C (solid-liquid mixture concentrations up to 60%).

Special Applications: Suitable for conveying highly abrasive media such as mud and slurry containing solid particles. It supports multi-stage cascade operation. Technical Advantages

Efficiency and Lifespan: Designed with wear resistance in mind and constructed from high-chromium alloy, these pumps achieve leading domestic efficiency.

Easy Maintenance: Compact construction minimizes maintenance space, ensuring smooth operation and high reliability.

Representative products include the 100D-A60 high-pressure slurry pump, suitable for the metallurgical and power industries. Its single-shell construction ensures stable performance even under high-pressure conditions.