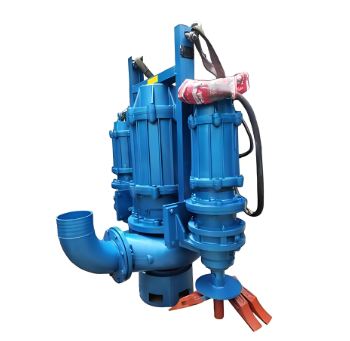

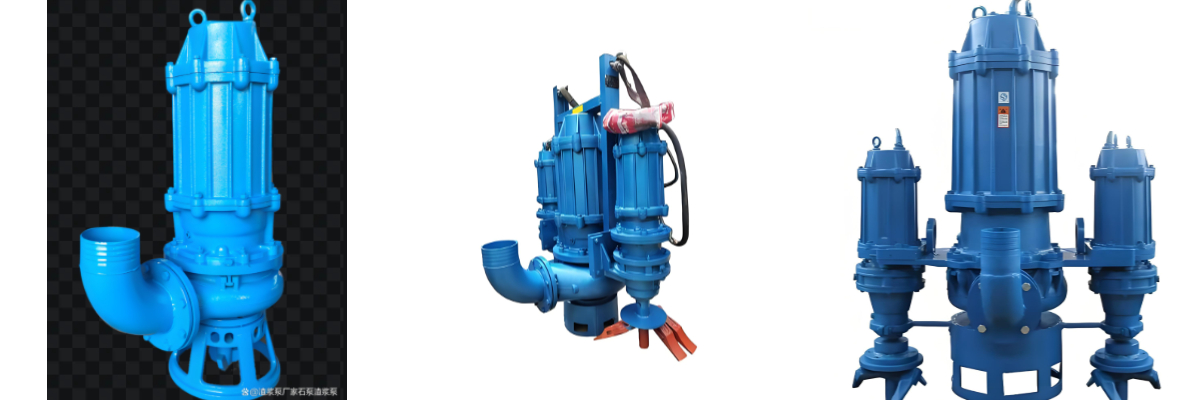

Mining Submersible Slurry Pump

High Head and Large Flow: Achieve high flow rates at high heads, such as tens to hundreds of cubic meters of slurry per hour.

Excellent Wear Resistance: Flow components (such as the impeller and pump casing) are constructed of high-chromium wear-resistant alloys to withstand erosion from solid particles such as slag and sand, allowing for thousands of hours of continuous operation before requiring replacement of wearing parts.

Submersible slurry pumps are slurry conveying equipment designed specifically for mining and other applications. They are primarily used to transport corrosive slurries containing solid particles and are suitable for applications such as mine drainage and coal slurry transportation. Key features include a highly wear-resistant design, explosion-proof motor, and intelligent monitoring capabilities, enabling them to withstand harsh environments up to 50 meters underwater.

Key Features

Material and Wear Resistance: Flow-through components are constructed of Cr27 high-chromium alloy (hardness ≥ 60 HRC), offering five times greater wear resistance and suitability for high-wear environments.

Motor Design: Equipped with a mining-grade explosion-proof motor and a water-filled circulating cooling system, they ensure safe operation in gaseous environments.

Optimized Structural: A dual-intake design balances axial water thrust and extends bearing life. The impeller utilizes a closed or semi-closed design to minimize energy loss.

Intelligent Features: Select models support mobile app-based remote monitoring, cloud data analysis, and automatic sewage disposal.

Applications

Mine Drainage: Suitable for underground coal mine dewatering, silt removal from silt tanks, and emergency rescue operations.

Mineral processing plant applications: Transporting slurries containing solid particles such as gangue and coal slime.

Environmental protection projects: Dredging and clearing river silt, hydraulic ash removal in thermal power plants, and other applications.

Selection Key Points

A comprehensive consideration should be given to factors such as operating conditions (such as slurry characteristics, head/flow requirements), motor power, and equipment corrosion resistance.