Centrifugal Sand Pump

The main advantages of centrifugal sand pumps include:

Compact structure and easy maintenance

Adopting motor direct connection structure, simple operation and maintenance, low daily maintenance cost.

Flexible flow regulation

The flow can be flexibly controlled by adjusting the speed or valve opening to meet the needs of different working conditions.

Stable and reliable operation

The impeller is designed to be balanced, the operation is smooth, the noise and vibration are small, and it is suitable for long-term continuous work.

Wide range of application

It can transport mortar media containing solid particles and is widely used in drilling, sand mining and other scenarios

Centrifugal sand pumps are frequently used in river dredging, mining, environmental protection and unique scenarios. They transport mud or gravel to a different neighborhood by using a high-speed rotating impeller. Its core factors consist of immoderate head, massive go with the go with the go with the flow and wear-resistant design, and are impressive for high-viscosity, solid-particle-containing media processing.

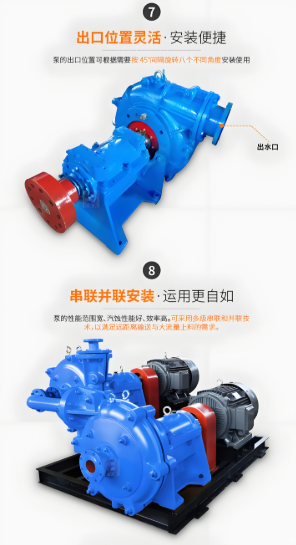

Structural features

The open impeller shape is fabulous for conveying high-viscosity drilling fluid or mud. The impeller is pushed through way of capability of a motor to rotate at immoderate tempo to generate centrifugal force, which throws the medium out from the suction port and discharges it with the useful resource of way of the pump casing. The sealing system adopts a blended sealing structure to extend the service life, and the each and every day format of factors such as bearing seats and shafts reduces protection costs.

Common fashions and parameters

AH sand pump : Displacement can acquire 46m³/h, head up to 46m, excellent for coal washing plant lifestyles in mines

50ZJ-I-A46 : Flow charge 65m³/h, head 46m, excellent for river sand removal and dredging projects

G gravel pump : Specific parameters pick to be personalized in accordance to customer needs

Applicable scenarios

River dredging, lake dredging

Sand and gravel transportation in mining

Mud remedy in environmental safety obligations

Maintenance points

For the first use, make fine that the mechanical seal and the packing sleeve are in a cozy kingdom to hold away from premature wear; after one 12 months of operation, the packing sleeve wishes to be adjusted to leak 3-8 drops per minute; when the wear-resistant sleeve is worn, the mechanical seal assembly needs to be replaced.