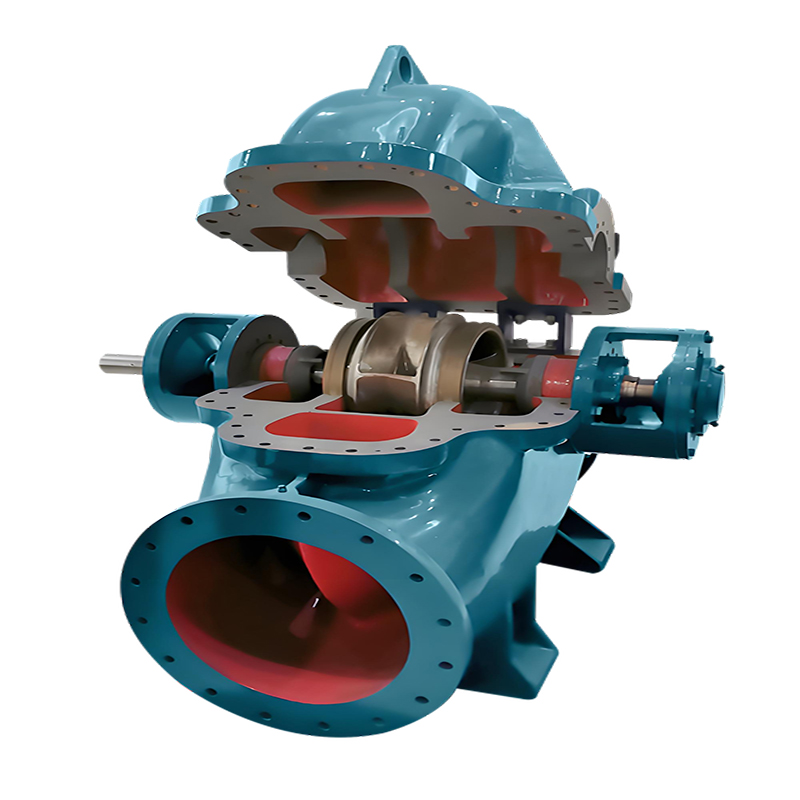

Double Suction Split Sase Pump

Compact structure: beautiful appearance, good stability, easy to install.

Smooth operation: The optimized double-suction impeller reduces the axial force to a minimum, and has a blade shape with excellent hydraulic performance, and is precision cast. The inner surface of the pump casing and the impeller surface are extremely smooth, with significant anti-cavitation performance and high efficiency.

Shaft seal: BURGMANN mechanical seal or packing seal is selected. It can ensure 8000 hours of operation without leakage. Bearing: SKF and NSK bearings are selected to ensure smooth operation, low noise and long service life.

Installation form: No adjustment is required during assembly, and it can be installed according to the on-site conditions. Separate or horizontal installation.

As an important form of centrifugal pump, double-suction pump is widely used in engineering because of its high head and large flow rate. The impeller of this pump type is actually composed of two back-to-back impellers, and the water flowing out of the impellers flows into a volute. The double-suction pump has the following characteristics: it is equivalent to two single-suction impellers of the same diameter working at the same time, and the flow rate can be doubled under the same impeller outer diameter; the pump casing is horizontally opened, which is convenient for inspection and maintenance. At the same time, the inlet and outlet of the double-suction pump are in the same direction and perpendicular to the pump shaft, which is conducive to the layout and installation of the pump and the inlet and outlet pipes; the impeller structure of the double-suction pump is symmetrical, there is no axial force, and the operation is relatively stable.

The suction port and discharge port of SH double suction clean water centrifugal pump are both below the axis of the water pump, and the horizontal direction is perpendicular to the axis. The pump casing is open. When inspecting, it is not necessary to dismantle the water inlet and outlet pipes and the motor (or other prime mover) from the coupling to the pump. The water pump rotates counterclockwise. If it is required by the user's special order, it can also be changed to clockwise rotation. The main parts of this type of pump are: pump body, pump cover, impeller, shaft, double suction sealing ring, sleeve, bearing, etc. Except for the shaft material which is high-quality carbon steel, the rest are mostly made of cast iron. The pump body and pump cover constitute the working room of the impeller. There are pipe screw holes for installing vacuum gauges and pressure gauges on the inlet and outlet flanges, and there are pipe screw holes for draining water at the bottom of the inlet and outlet flanges. The impeller is statically balanced and fixed with a sleeve and sleeve nuts on both sides. Its axial position can be adjusted through the sleeve nut. The axial force of the impeller is balanced by the symmetrical arrangement of its blades. There may be some residual axial force that is borne by the bearing at the coaxial end. The pump shaft is supported by two single-row radial ball bearings, which are installed in the bearing bodies at both ends of the pump body and lubricated with butter. The double suction seal ring is used to reduce the water leakage from the water pump pressure chamber back to the water suction chamber. The water pump is directly driven by the motor through the coupling. The shaft seal is a soft packing seal. In order to cool and lubricate the seal cavity and prevent air from leaking into the pump, there is a water seal ring between the packing. When the water pump is working, a small amount of high-pressure water flows into the packing cavity through the water seal pipe to act as a water seal.