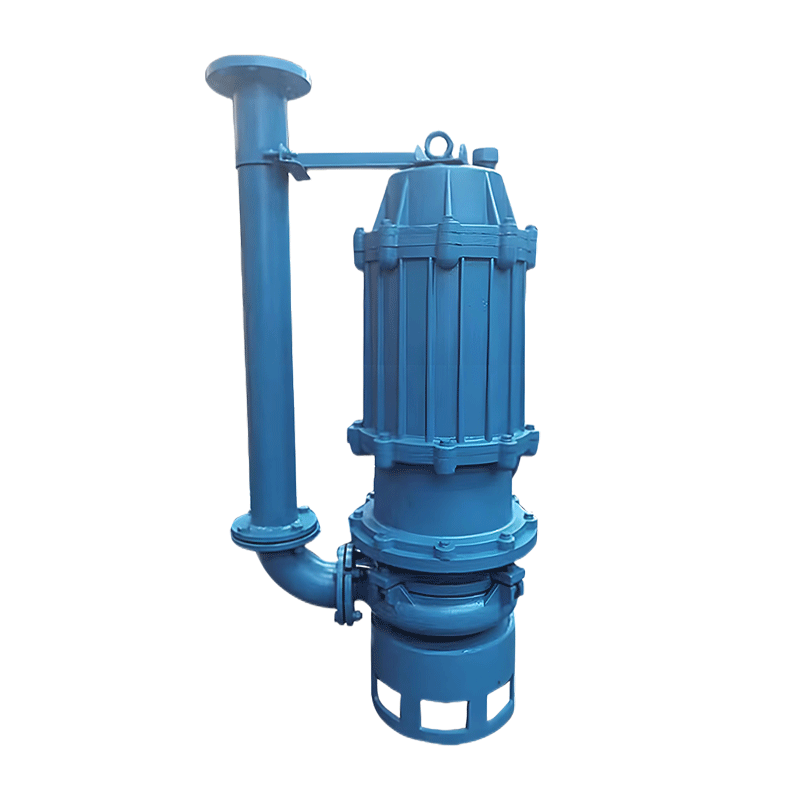

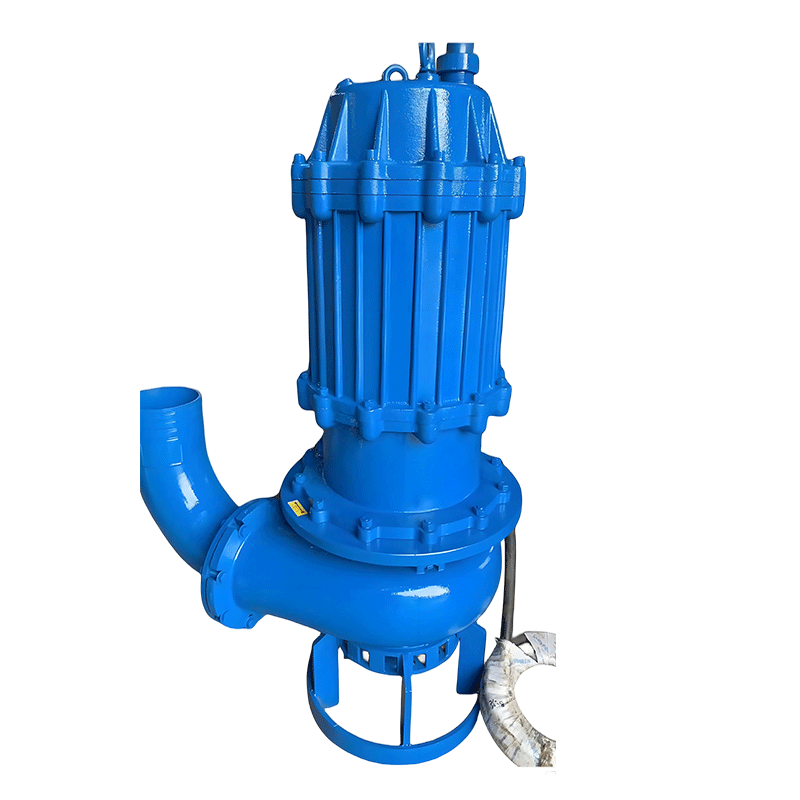

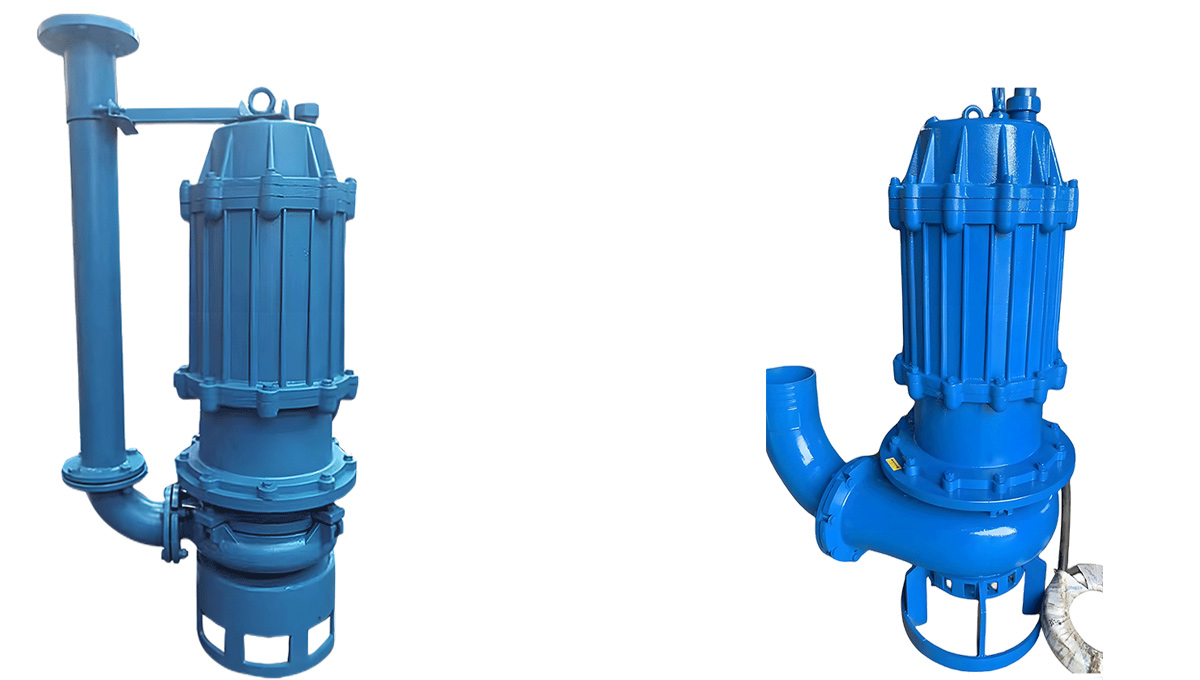

Wear Resistant Submersible Slurry Pump

1. The whole machine is a dry motor pump structure. The motor is protected by a mechanical seal, which can effectively prevent high-pressure water and impurities from entering the motor cavity.

2. In addition to the main impeller, there is also a stirring impeller, which can stir the sludge deposited at the bottom of the water into turbulence and then extract it.

3. The main flow-through parts such as the impeller and the stirring impeller are made of highly wear-resistant materials, which are wear-resistant, corrosion-resistant, non-clogging, and have strong sewage discharge capacity, and can effectively pass larger solid particles.

4. It is not limited by the suction range, has high slag suction efficiency, and is more thorough in dredging.

ZJQ wear-resistant submersible slurry pump is a hydraulic machine with a motor and a water pump coaxially submerged in the medium. The product is made of fine materials, has advanced structure, wide flow passage, strong sewage discharge capacity and strong corrosion resistance. It is suitable for conveying liquids containing solid particles such as sand, coal slag, tailings, etc. It is mainly used for the removal and transportation of mud liquids in metallurgy, mining, thermal power plants and other enterprises. It is an ideal substitute for traditional mud pumps.

ZJQ wear-resistant submersible slurry pump series products are designed and manufactured by absorbing foreign advanced technology. The use of high-tech wear-resistant materials greatly increases the life of the equipment and reduces the frequency of maintenance. In addition to the main impeller, the water pump adds a set of stirring impellers at the bottom, which can spray the precipitated sludge into turbulence. The high-concentration slurry formed is just located at the suction port of the main impeller, so that the water pump can achieve high-concentration transportation without auxiliary devices. The unique sealing device can effectively balance the pressure inside and outside the oil chamber, so that the pressure at both ends of the mechanical seal is balanced, which maximizes the reliability of the mechanical seal and greatly extends its service life. The motor adopts multiple protection measures such as overheating and water inlet detection, which can operate safely for a long time under harsh working conditions. According to user requirements, protective measures such as motor anti-condensation and bearing temperature measurement can also be added to meet user use in different occasions.

Product Advantages:

The ZJQ submersible slurry pump is a coaxial water pump and motor. When working, the motor shaft drives the water pump impeller to rotate, transfers energy to the slurry medium, generates a certain flow rate, drives the solids to flow, and realizes the transportation of slurry.

Its main features are as follows:

1. No auxiliary vacuum pump is required, and the investment is lower.

2. No auxiliary stirring or spraying device is required, and the operation is simpler.

3. The motor is submerged in water, and there is no need to build complex ground protection and fixing devices, which makes management easier.

4. The impeller directly contacts the sedimentation surface, and the concentration is controlled by the diving depth, so the concentration control is more flexible.

5. The equipment works directly underwater, without noise and vibration, and the site is cleaner.

Company Strength:

Hebei Grandwatt Pump Industry Co., Ltd. has been deeply rooted in the water pump industry for many years, committed to delivering efficient and reliable pumping solutions to customers worldwide. With a modern manufacturing base covering over 30,000 square meters, our factory is equipped with intelligent production lines and advanced testing equipment. We boast an annual production capacity of more than 200,000 units, offering a comprehensive range of products including industrial pumps, submersible pumps, centrifugal pumps, and sewage pumps.

Our products are widely used in municipal engineering, agricultural irrigation, industrial circulation, and building water supply, among other sectors.