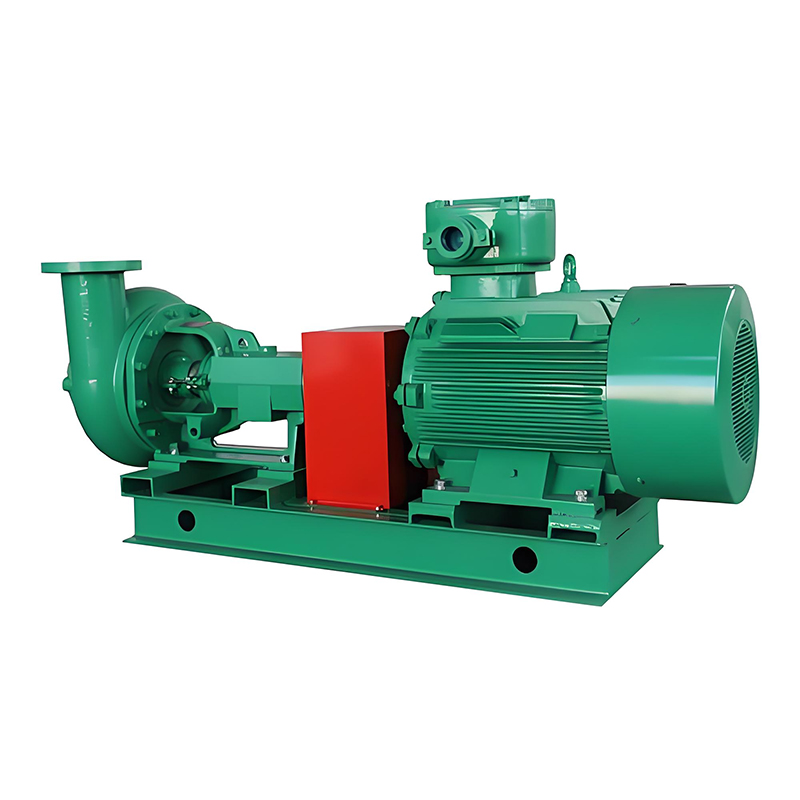

Horizontal Sand Pump Nice

The flow-through parts (such as pump body, impeller, and guard plate) made of high-chromium alloy or chromium 26 alloy have strong wear resistance and are suitable for conveying high-concentration slurry or corrosive media.

Through the optimization of the hydraulic model design, the efficiency can reach 78%-82%, the flow range covers 500-6000m³/h, and the head can reach up to 45 meters, which is suitable for large flow and low head scenarios.

The sand pump is a power equipment for conveying highly abrasive media such as yellow sand, mineral sand, and tailings slurry. It belongs to the category of centrifugal mud pumps and is widely used in river dredging, reclamation, industrial and mining tailings processing, and gold panning. It is mainly driven by a motor or a diesel engine, and can convey a solid-liquid mixture with a concentration of up to 60%, a maximum mixed flow rate of 5,000 cubic meters per hour, and a pumping depth of up to 30 meters underwater. It has the characteristics of high efficiency, wear resistance, and high head.

The equipment is divided into horizontal, vertical, and submersible types according to the structure. The horizontal pump adopts a centrifugal design, and the flow parts can be made of cast iron or alloy. It is suitable for inland and coastal sediment transportation; the vertical pump is often used with a high-pressure clean water pump for dredging of water conservancy projects, supporting long-distance pipeline transportation; the submersible pump motor is coaxial with the pump body, equipped with a high-pressure sealing device, and can extract large-particle sediments. The wear-resistant type is made of high-chromium alloy or chromium 26 alloy, which is suitable for high-concentration slurry; the non-metallic wear-resistant type is made of lightweight materials and is specially designed for silty sand. The main components include pump body, impeller and guard plate. During maintenance, attention should be paid to the adjustment of impeller clearance and bearing lubrication cycle.

It is a impurity pump designed with reference to the two-phase flow theory, divided into: 250PN-30, 250PN-35, 250PN-40, 350PN-24, 350PN-35, 350PN-45, 400PN-22. After experiments and industrial operation tests, the pump has the characteristics of high hydraulic efficiency and good wear resistance, and stable performance when conveying media containing solid particles. The pump is suitable for inland river dredging, coastal embankment land reclamation, and coal mines, mines, power plants and other enterprises to convey slurry containing solid particles, etc. The conveying medium concentration can reach more than 40%, and the medium particles can reach 50 mm. Scope of application: 1. Suitable for inland river dredging, coastal embankment land reclamation, and pumping mud and yellow sand from rivers, lakes, seas and reservoirs. 2. Coal mines, mines, power plants and other enterprises convey slurry containing solid particles, etc. The conveying medium concentration can reach more than 40%, and the medium particles can reach 50 mm. Auxiliary equipment: An emptying device needs to be installed. Structural features: 1. It is mainly composed of pump body, impeller, guard plate, pump cover, bracket and bearing assembly. 2. The materials of pump body, impeller and guard plate can be made of gray cast iron, cast steel, wear-resistant alloy and non-metallic wear-resistant materials. Users can choose according to the purpose when ordering. 3. The shaft seal of the pump adopts packing seal, and high-pressure flushing water is added to the packing chamber to better ensure the normal operation of the pump. 4. The direction of the pump is counterclockwise from the water inlet, and the outlet of the pump is on the right side of the horizontal direction from the water inlet. If the water outlet is required on site, it can be adjusted within 360 degrees. Material: The pump shell can be ordinary cast iron, cast steel, alloy. The material of impeller and guard plate can be made of cast iron, cast steel, wear-resistant alloy and non-metallic wear-resistant materials. Users can choose according to the purpose when ordering. Features: The advantages are large flow rate, wide flow channel, can transport various mud and sand media, a variety of materials are available, and flexible adaptation to various working conditions.